Our Materials Database is an accumulation of materials used with our AM1. Each material has a profile indicating the associated settings and recommendations, creating a catalog of hundreds of materials for our customers. The database has our known suppliers, vendors, and resins for our users to choose from. In the Cosine Dashboard, we offer an opportunity to send feedback to help the software team improve the database for a better experience.

Contact us today to start using our Materials Database with your AM1!

AM1 YouTube Tutorials

Learn how to operate America's best large scale 3D printer with our new tutorial series! More tutorials are on the way, so stay tuned on our Youtube: http://bit.ly/2xF2zOu

September Newsletter

Click the video to see how Cosine prioritizes our customers through Mike Ibarra, Engineering Manager at KW Industries. To experience Cosine's great customer service, contact us to start your project today!

With the devastating wreckage Hurricane Harveyleft behind, we give our condolences to those affected in our great city of Houston. We thank those who have checked on Cosine's well being and assure that our facility is still up and running, providing our best quality service like we have always done! Visit our website to see how Cosine can best serve you!

GSA Approved

Cosine has now joined with GSA to establish relationships with potential government buyers. Now GSA Approved, Cosine's equipment and services are obtainable through the GSA Multiple Awards Schedule, which provides a fast and efficient way to purchase the company's products and services. For more information, visit https://www.gsa.gov/.

KW Industries Testimonial

KW Industries has been one of our valued customers for over a year now. Watch the video to see how Cosine prioritizes our customers through Mike Ibarra, Engineering Manager at KW Industries. To experience Cosine's great customer service, contact us to start your project today!

Great R&D Success for University of Wisconsin-Madison

For the past couple of years, the University of Wisconsin-Madison has been experimenting with 3D printing heat exchangers for power plants. After succeeding, the government is funding to continue with the development of heat exchangers for refrigerators. With the help of Cosine and other companies, the University of Wisconsin-Madison will continue in furthering the success of this project. Start your project today to see where success will take you!

Positive Ratings for Cosine Additive

Cosine Additive received a positive rating from Lux Research! Here at Cosine, we strive to be at the top of the additive manufacturing industry. From manufacturing our AM1 to printing sample parts, we welcome customers and reviewers onsite and online to experience Cosine, firsthand. Contact us to start your project today and see for yourself. Click here to read Lux Research's review on us.

August Newsletter

Need parts printed? We print parts. Our printing services page is up and running! Offering services from printing to surface finishes, we can help with your project step by step, making it easier to start your project with us. Visit our printing services page to learn more and request a print today.

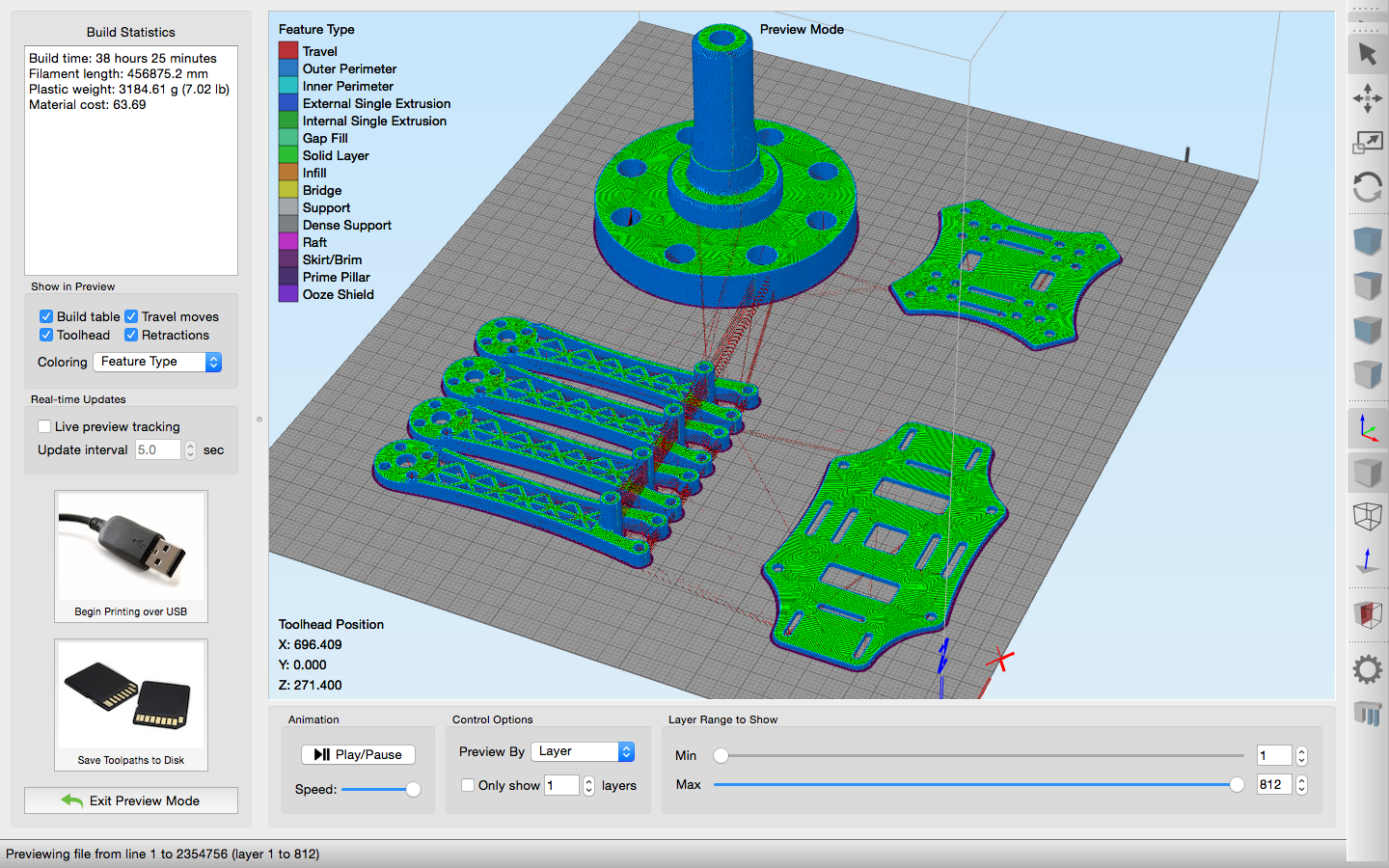

Simplify3D has added new features and updates to their slicer program, improving on more options to make slicing easier. Cosine is excited to share these updates with you as we work together to slice your project. Learn more on our blog or contact us to start your project today!

The Advanced Manufacturing Expo is coming up soon, on August 24 in Grand Rapids, MI! Visit booth 210 to meet our CEO, Jason Miller (right), and our Director of Technical Support and Customer Service, Jacob Jacobson (left). Don't forget to ask them about our recent developments!

Simplify3D Upgrades to Version 4.0

Simplify3D has updated their slicer system making 3D printing faster and easier than ever! With a wider range of settings and better options to support your part, the slicer program focuses on the precision and quality of your print all at the control of your fingertips. Cosine is excited to share these new improvements with you! Contact us to start your project today with the updated slicer program.

Features:

- Variable print settings

- Preview your processes

- Seamless process transitions

- Drag and drop reordering

- Improved Sequential printing

- Dual customizations

- Variable Extrusion Settings

- Dynamic Gap Fill

- And many more….

MIT Offers Additive Manufacturing Classes

MIT is offering Additive Manufacturing classes during July 31-August 4. With learning materials from Cosine and other industry experts, the class has something to offer individuals of every level. Whether you are a beginner or an expert, you are bound to learn something new! Sign up with MIT to see what there is to learn and for more info contact us today!

July Newsletter

Our Cosine intern, Maria Mora Sanchez, is an industrial design student at the University of Houston. She partnered with us to bring her thesis to life. Click on the video to learn more about the future of fashion and her dress printed with our AM1!

MIT Additive Manufacturing Class

The first day of the Additive Manufacturing class for MIT is July 31st! With learning materials from Cosine and other industry experts, the class has something to offer individuals of every level. Whether you are a beginner or an expert, you are bound to learn something new!

The Advanced Manufacturing Expo is coming up soon, on August 24 in Grand Rapids, MI! Visit booth 210 to meet our CEO, Jason Miller, and our Director of Technical Support and Customer Service, Jacob Jacobson. Don't forget to ask them about our recent developments

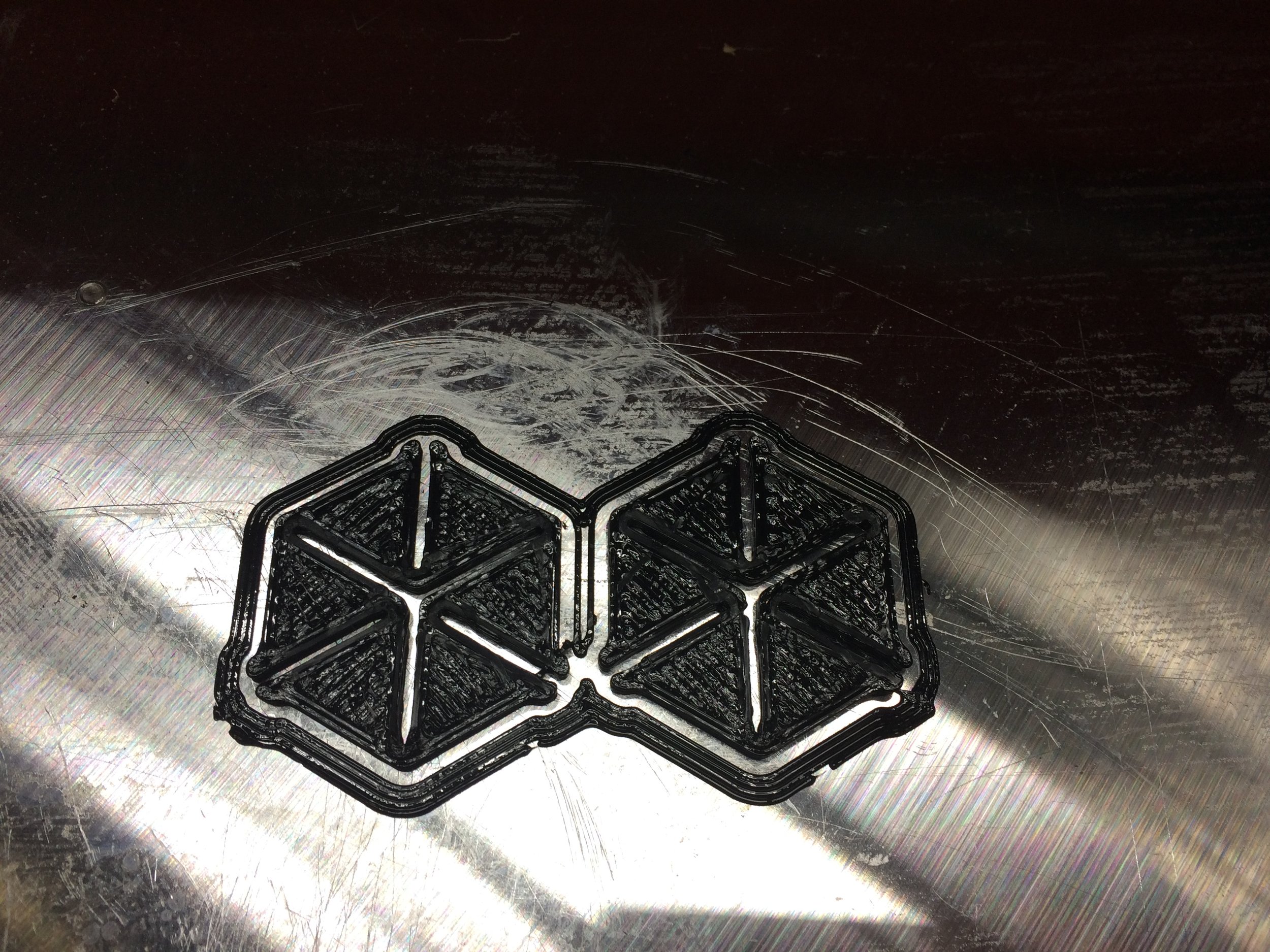

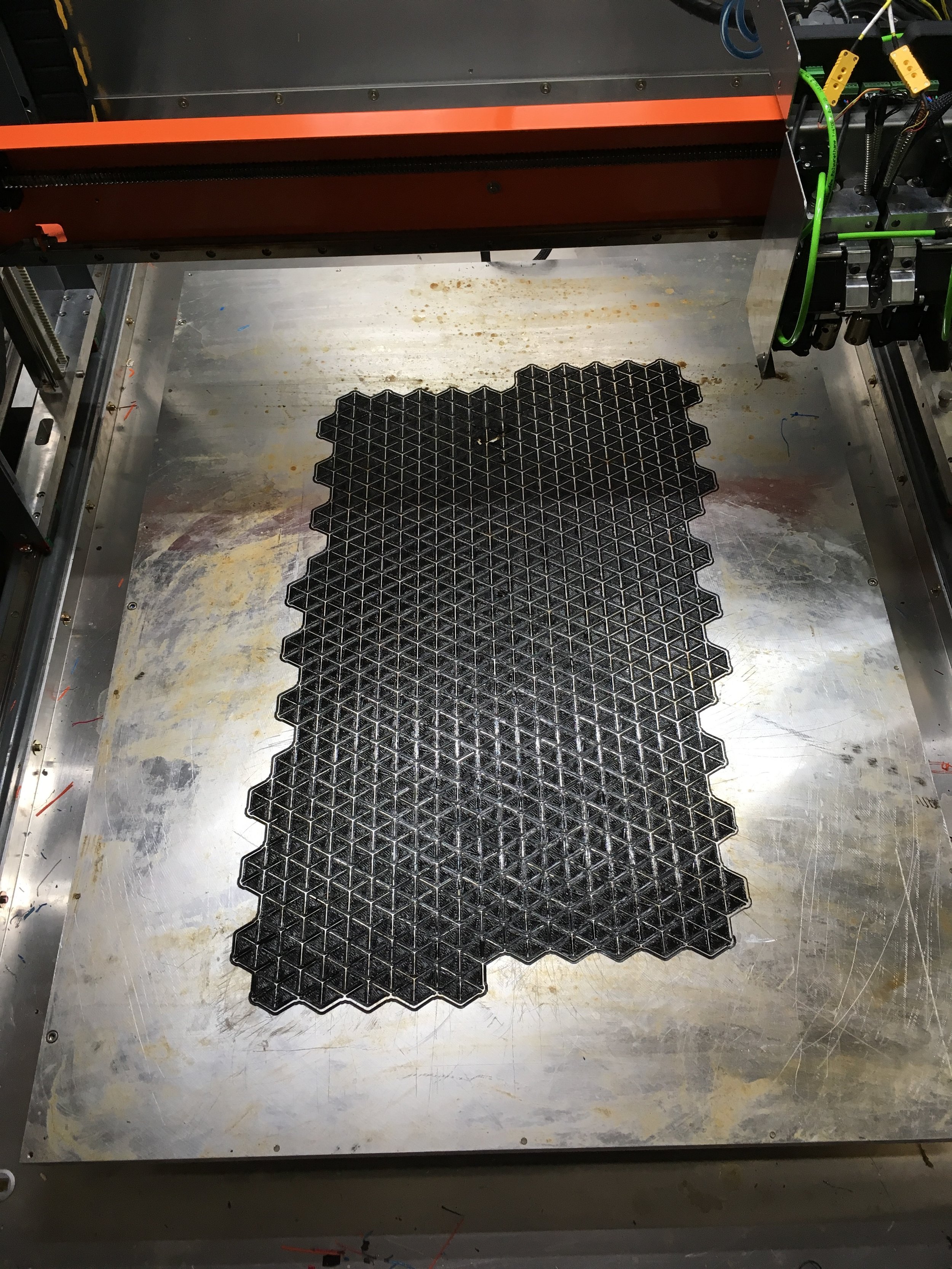

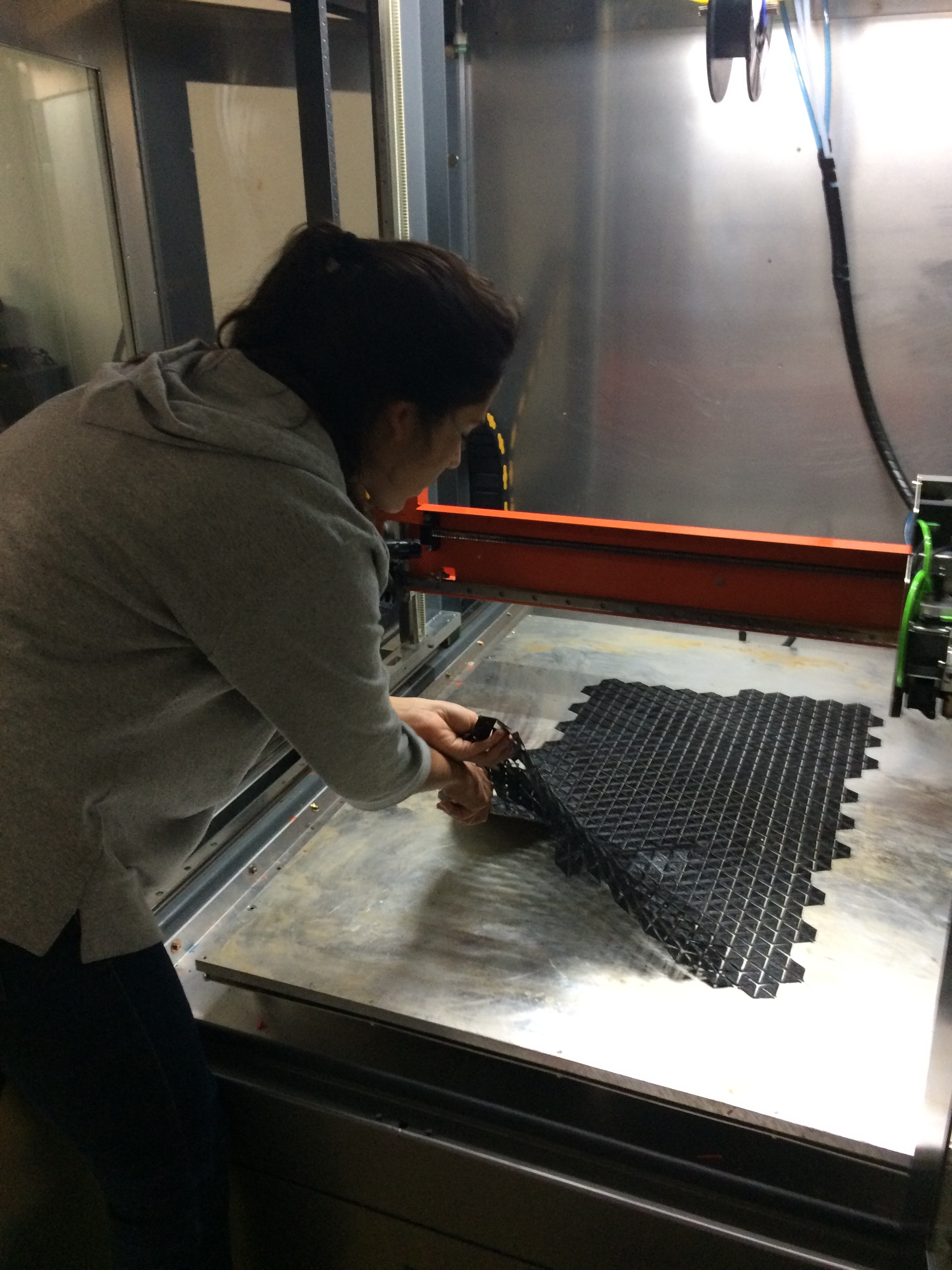

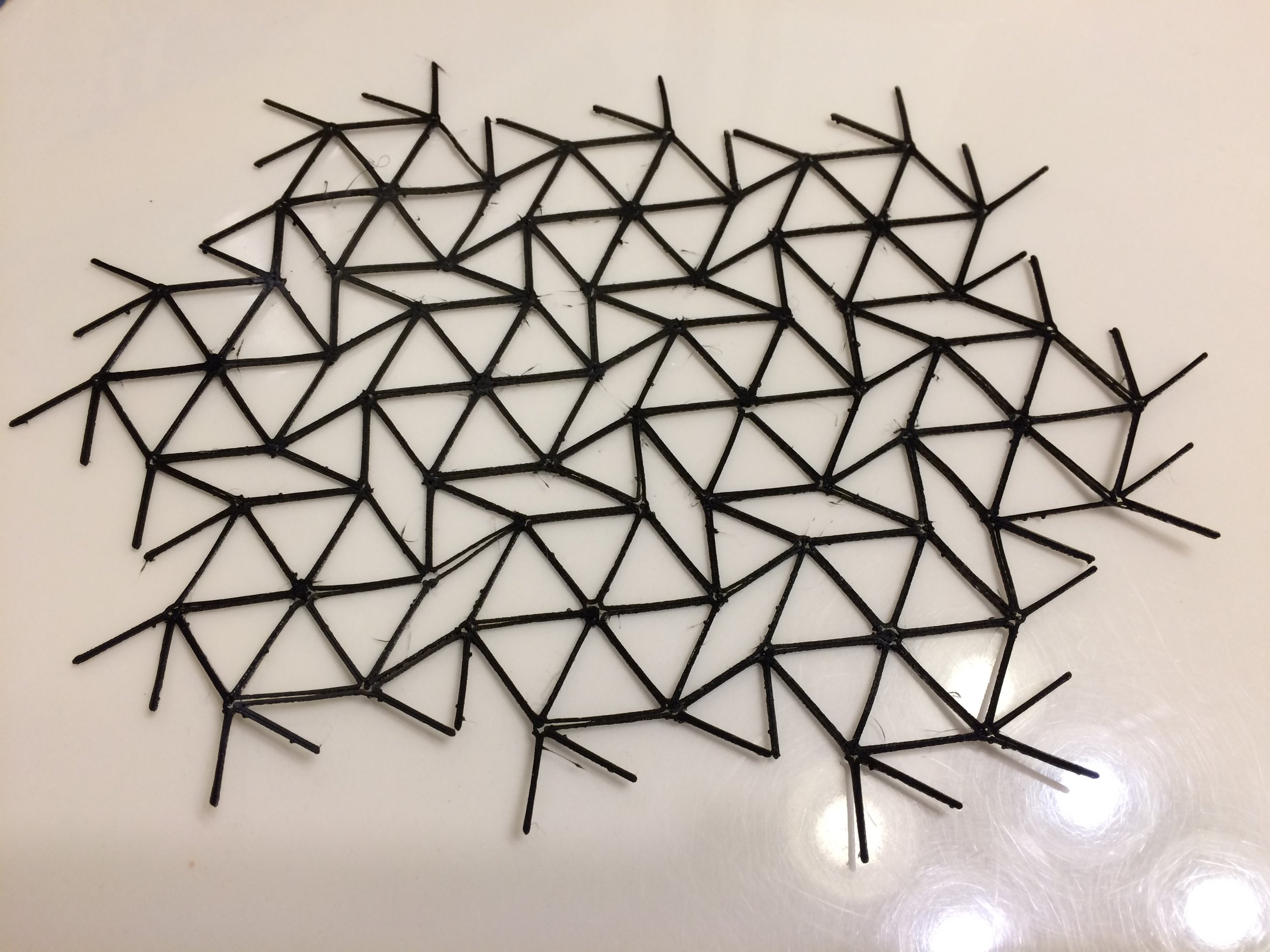

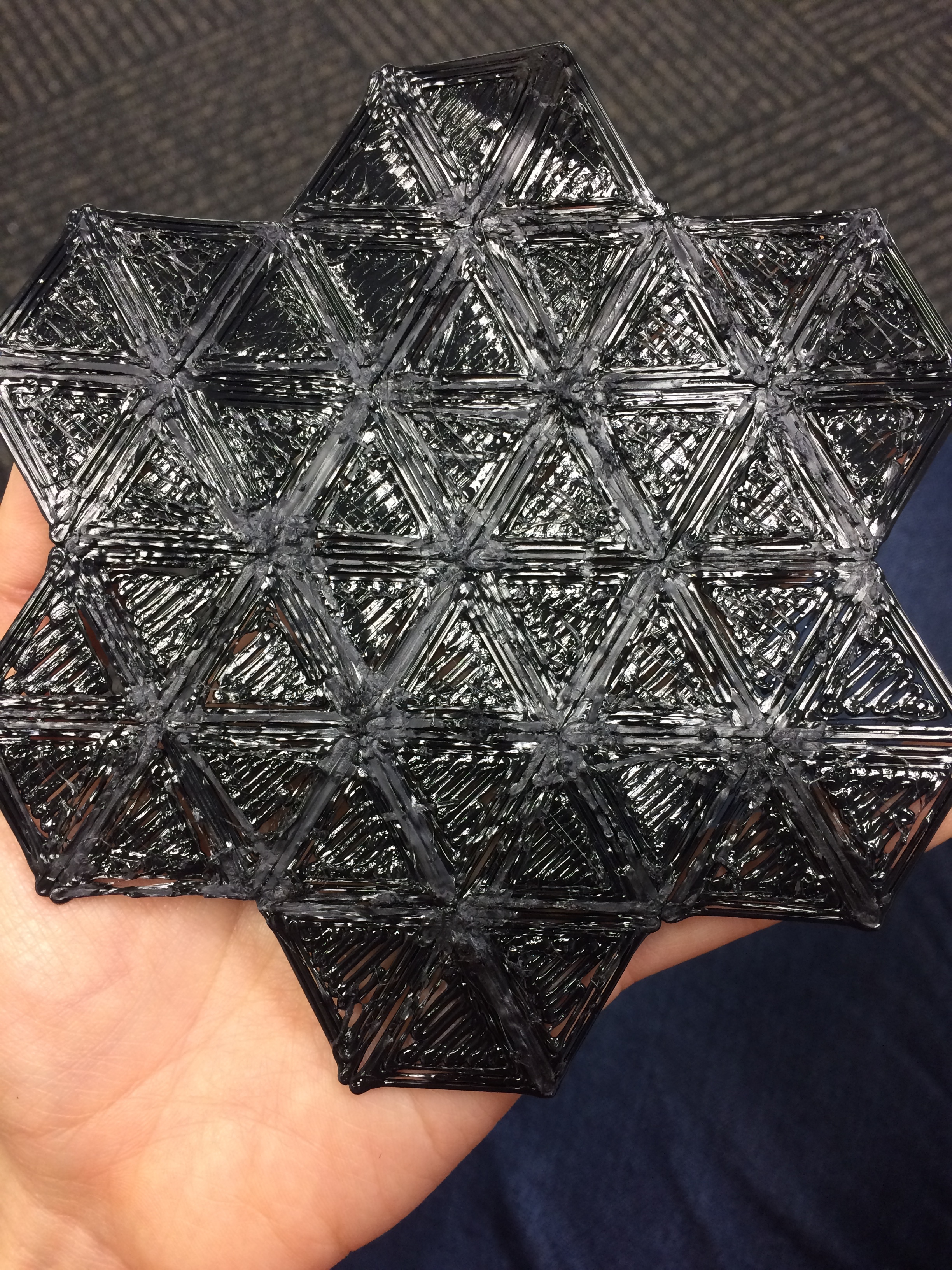

3D Printed Textiles

UNDERSTAND

THE PROBLEM

I believe that 3D printing is the future of fashion. With the current developments we are experiencing in this technology there are a great number of opportunities to create amazing new products and materials. Since we aren’t able to 3D print fabrics yet, I decided to team up with Cosine Additive and focus my thesis in designing flexible, adaptable, fashionable patterns. The intent is to explore the possibilities of creating wearable ‘textiles’ with structures that are designed in relation to function and materialization through anatomy, movement and utility. As far as additive manufacturing and the fashion industry are concerned they are mainly focused in accessories and conceptual sculptural pieces. However, these aren’t functional garments that adapt comfortably to the body and to human movement. Through this explorative project I hope that I can contribute into the future of fashion.

Designer:

Maria Alejandra Mora-Sanchez

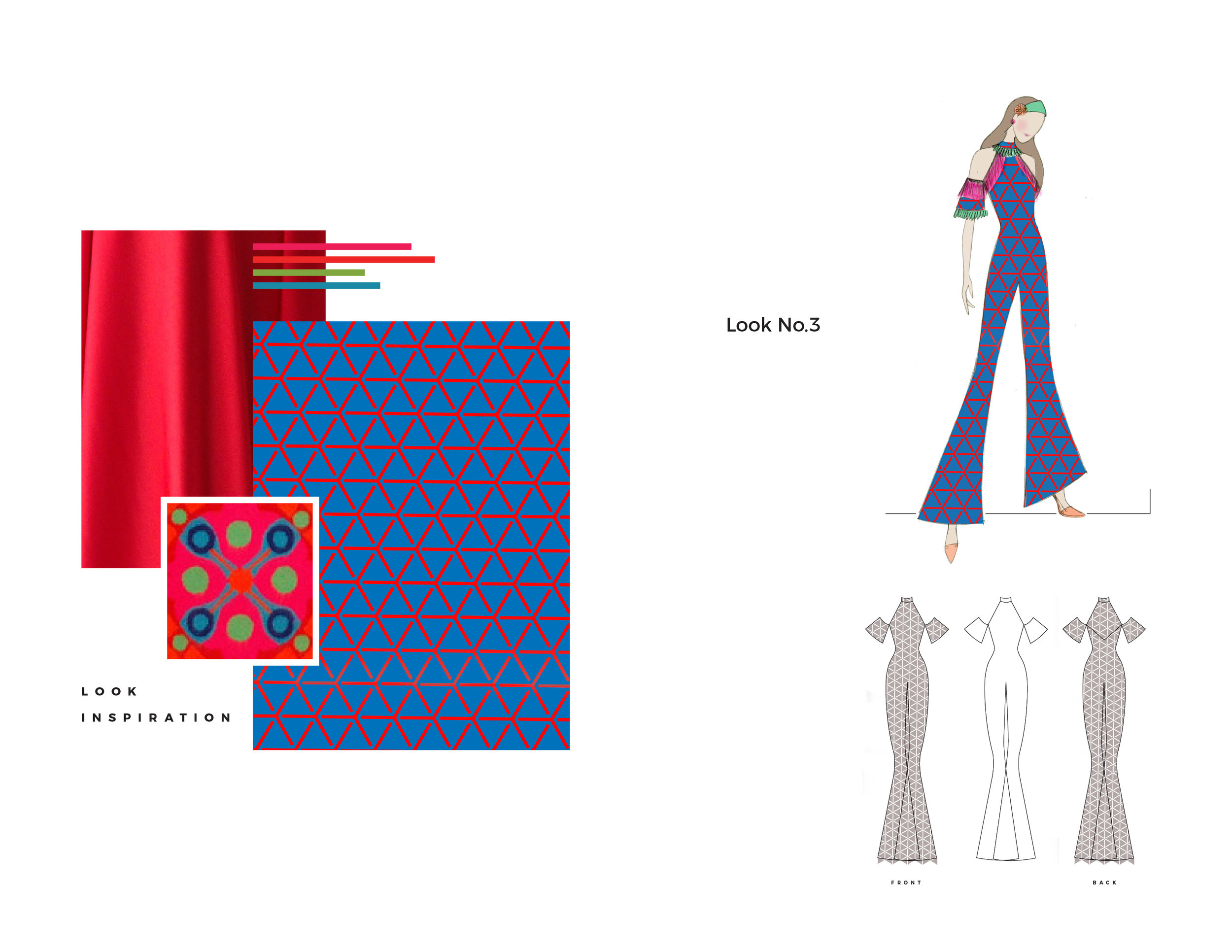

WAYUU

SPRING 2019 COLLECTION

EXPLORATION OF 3D PRINTED FABRICS

INSPIRED BY THE TRADITIONAL WAYUU TEXTILES

The WAYUU tribe is an indigenous community of the Guajira Peninsula in northern Colombia and northwest Venezuela. They are well known for textiles, crafts and patterns which are inspired by nature and the tribe's surrounding environment.

MARACAIBO, VENEZUELA

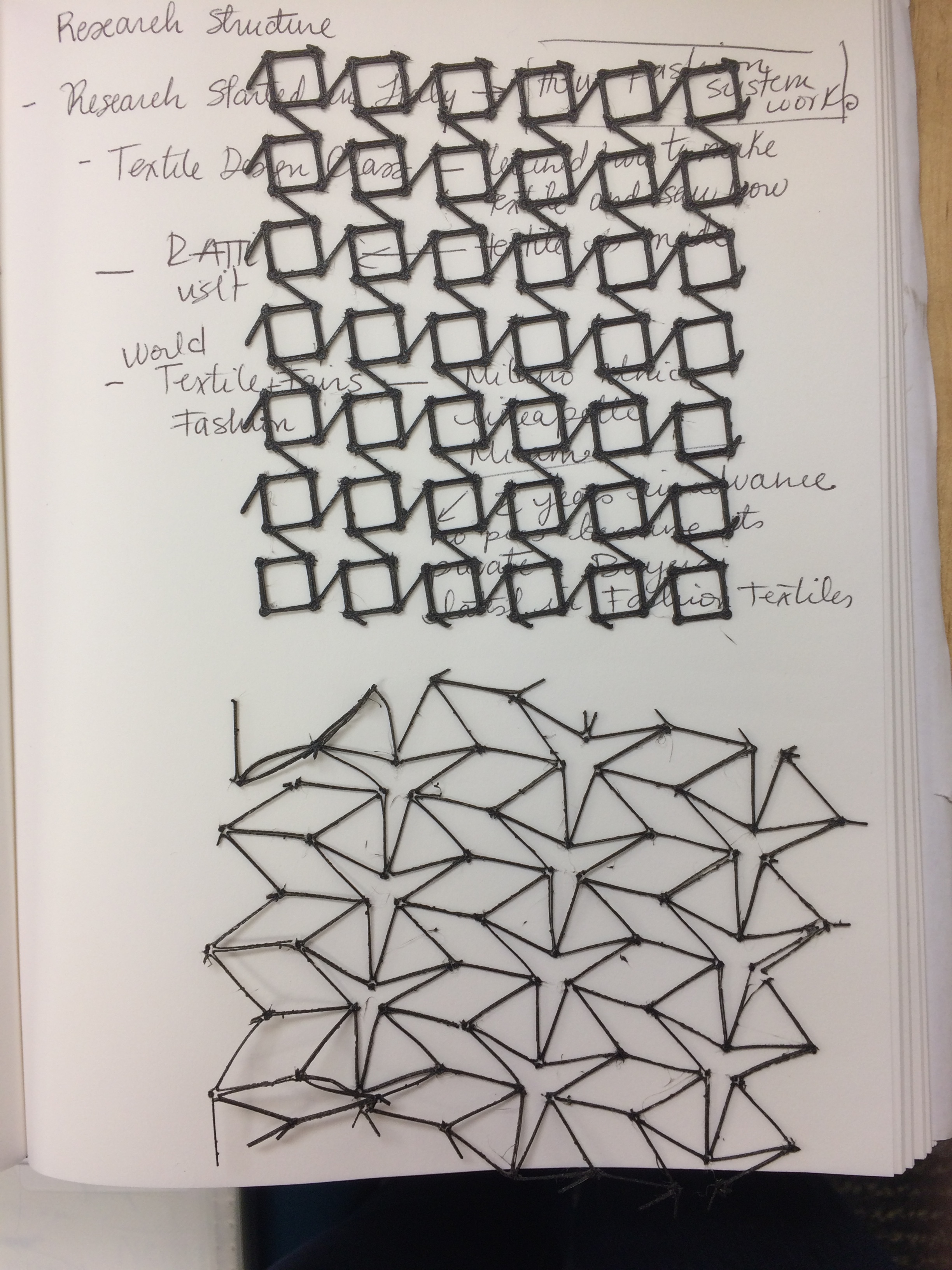

EXPLORE

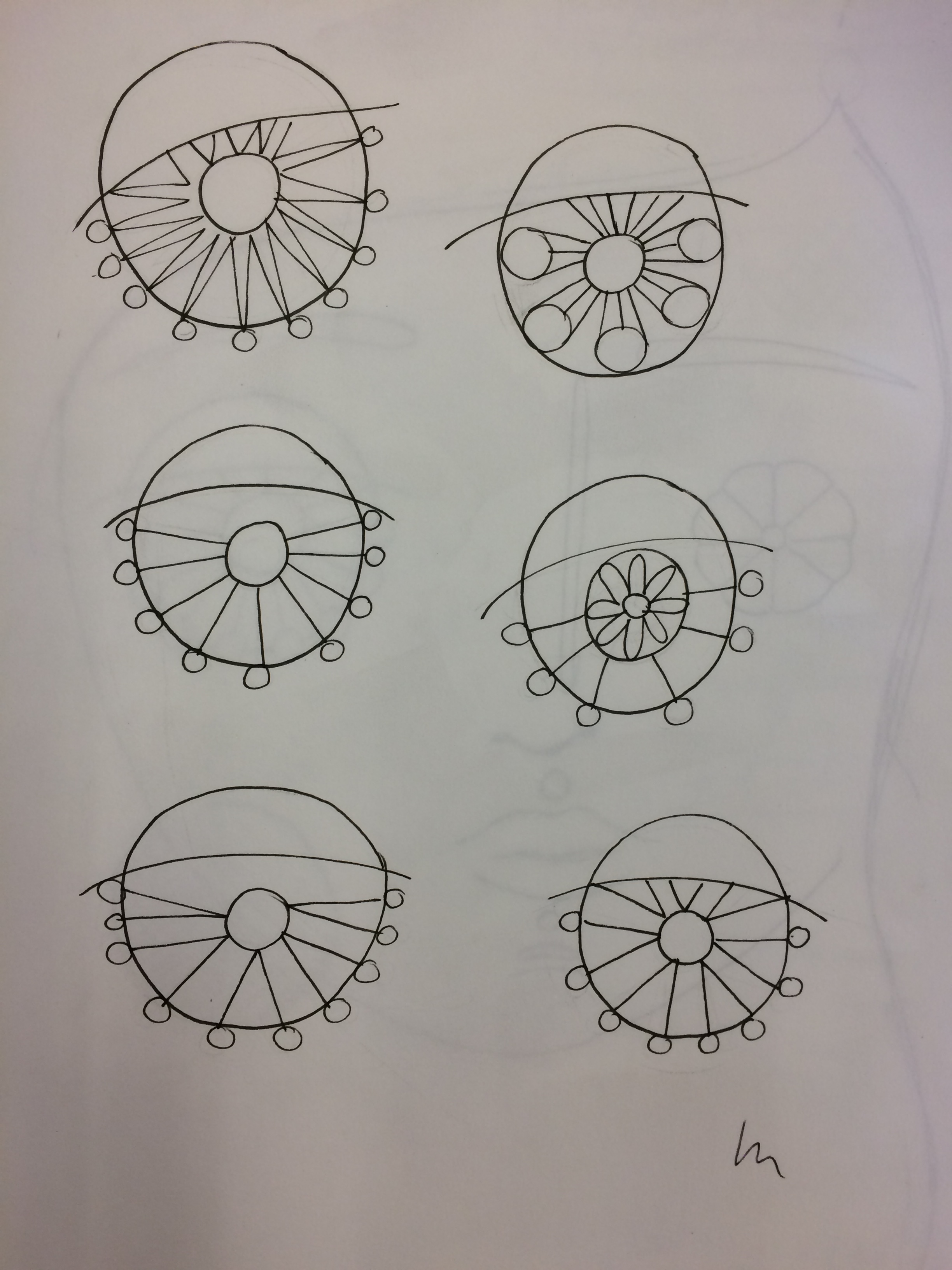

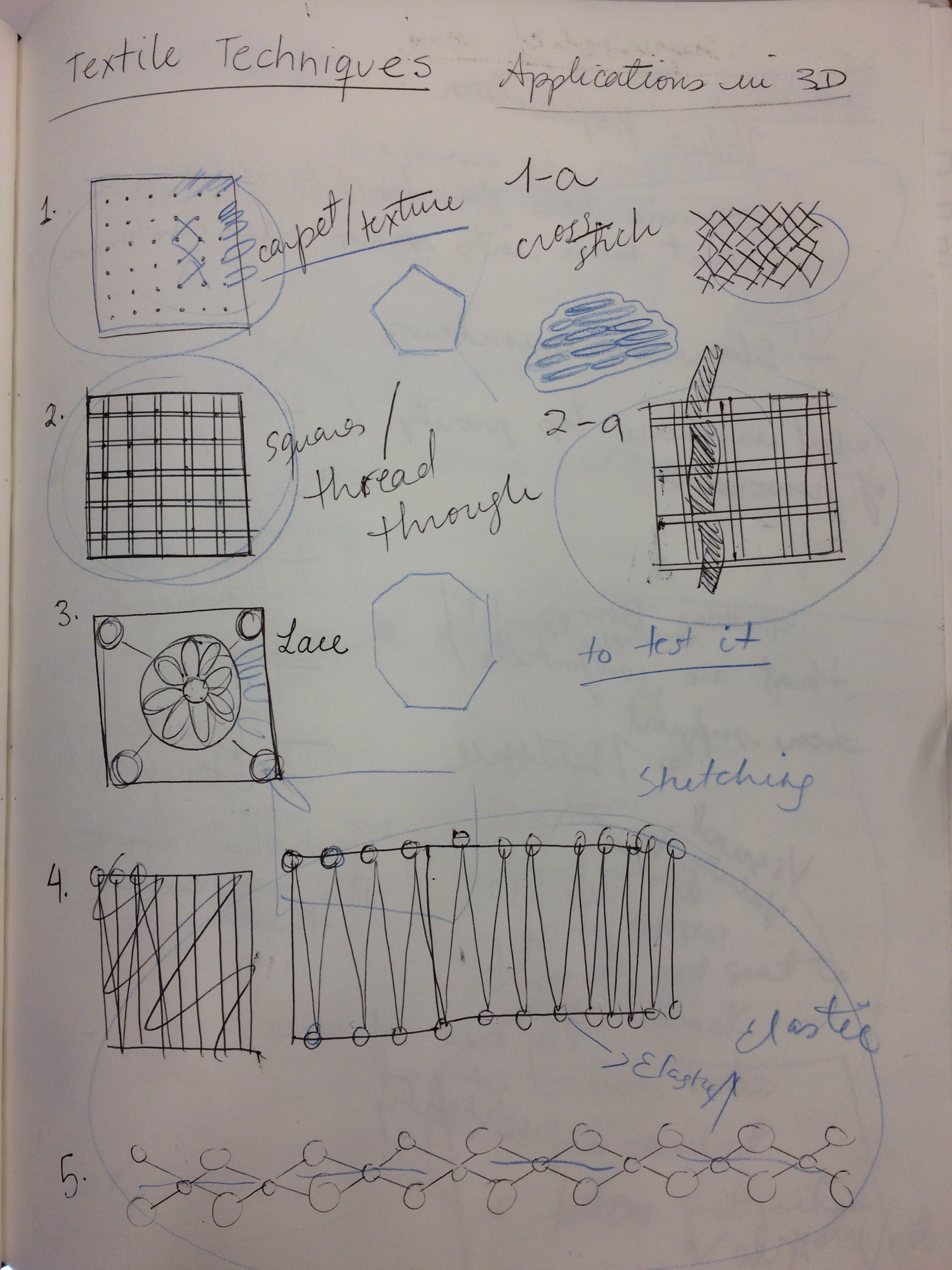

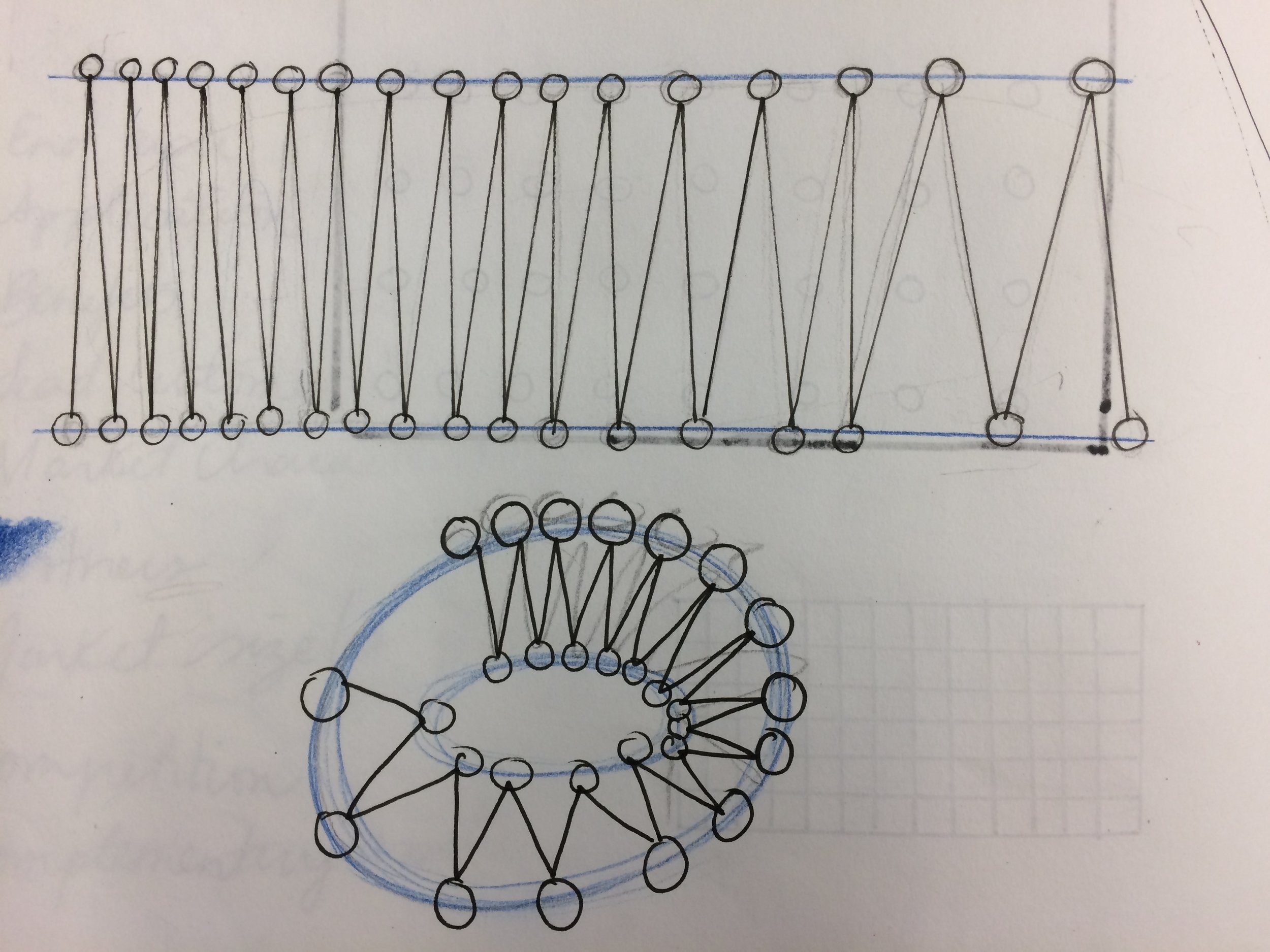

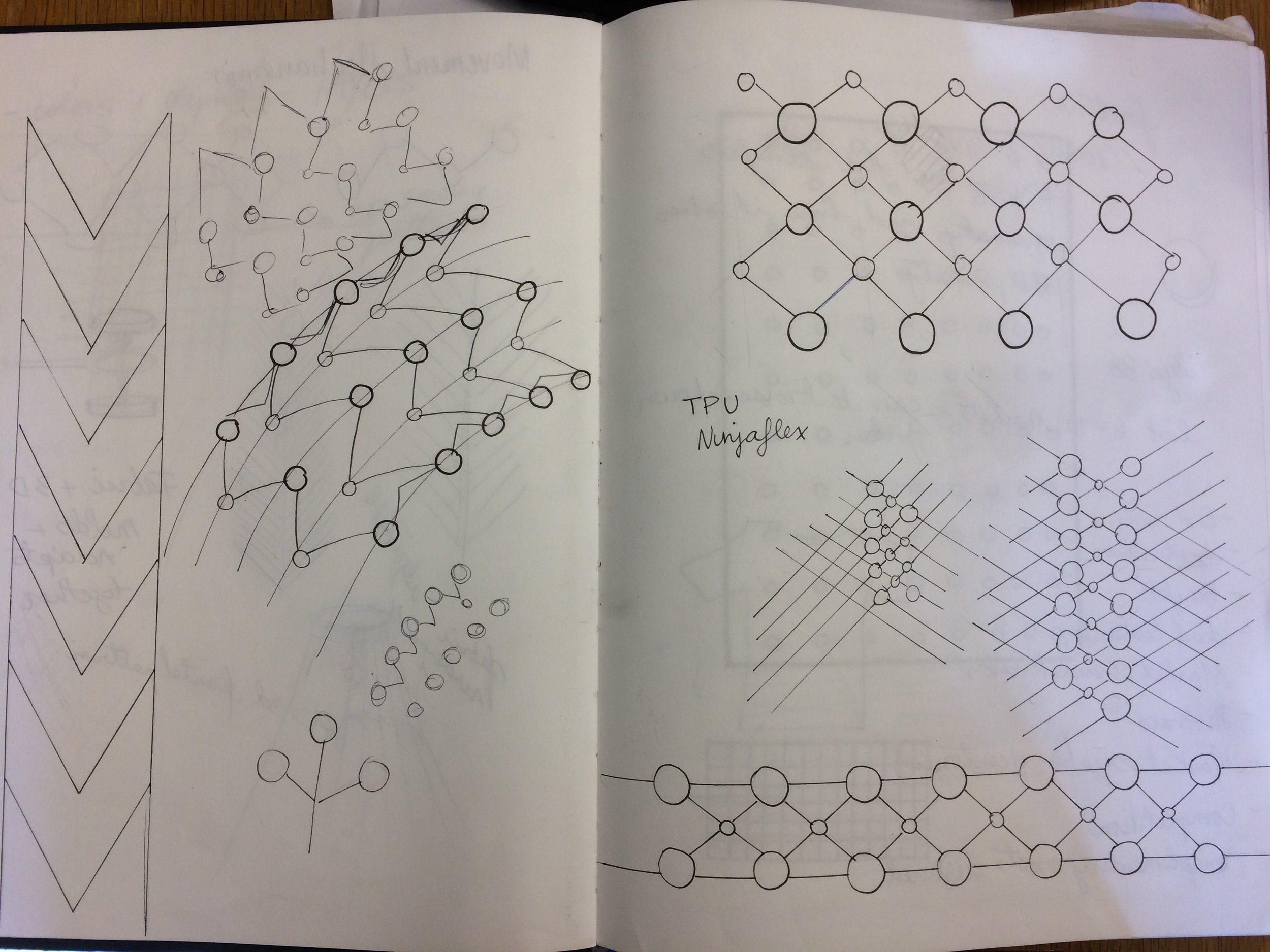

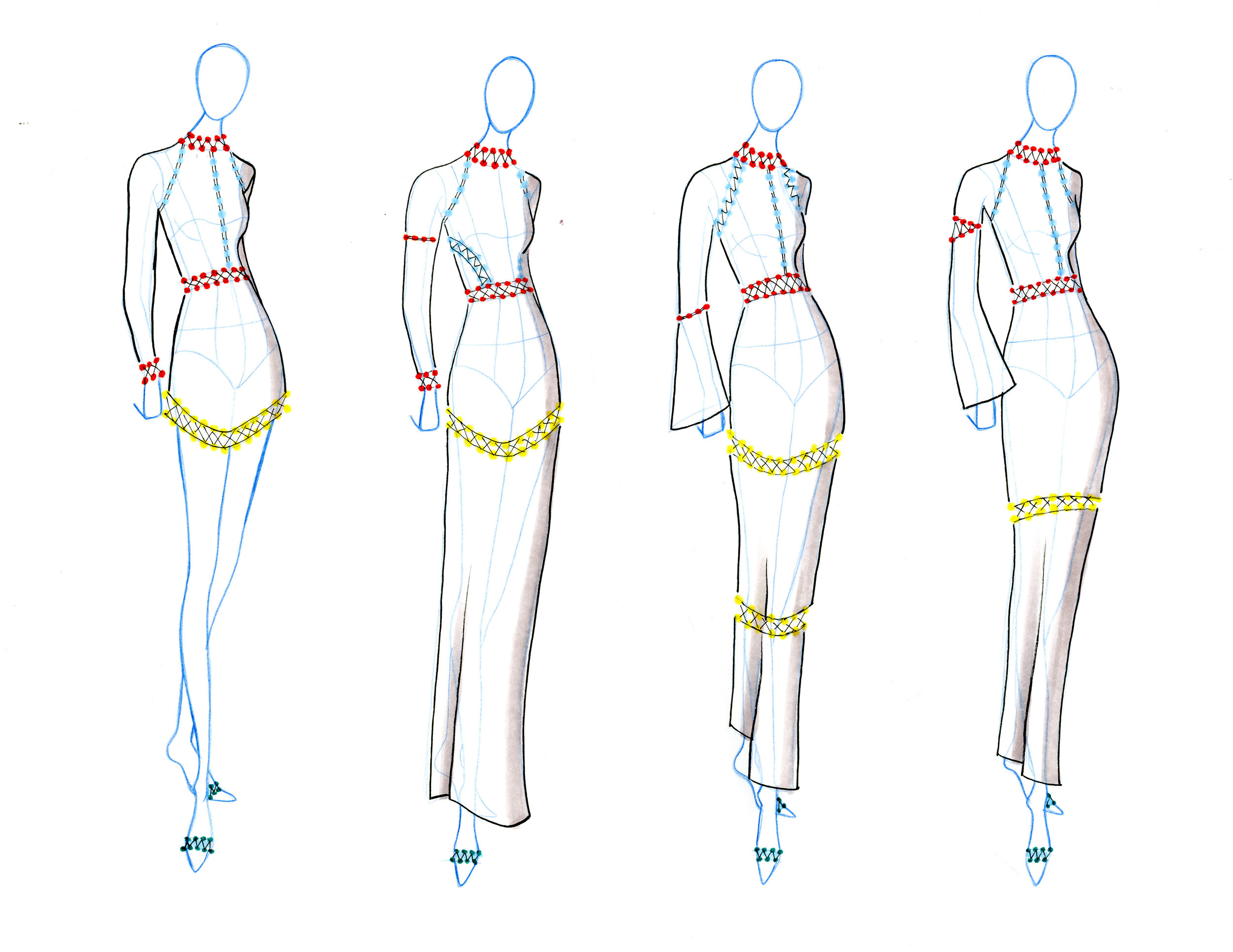

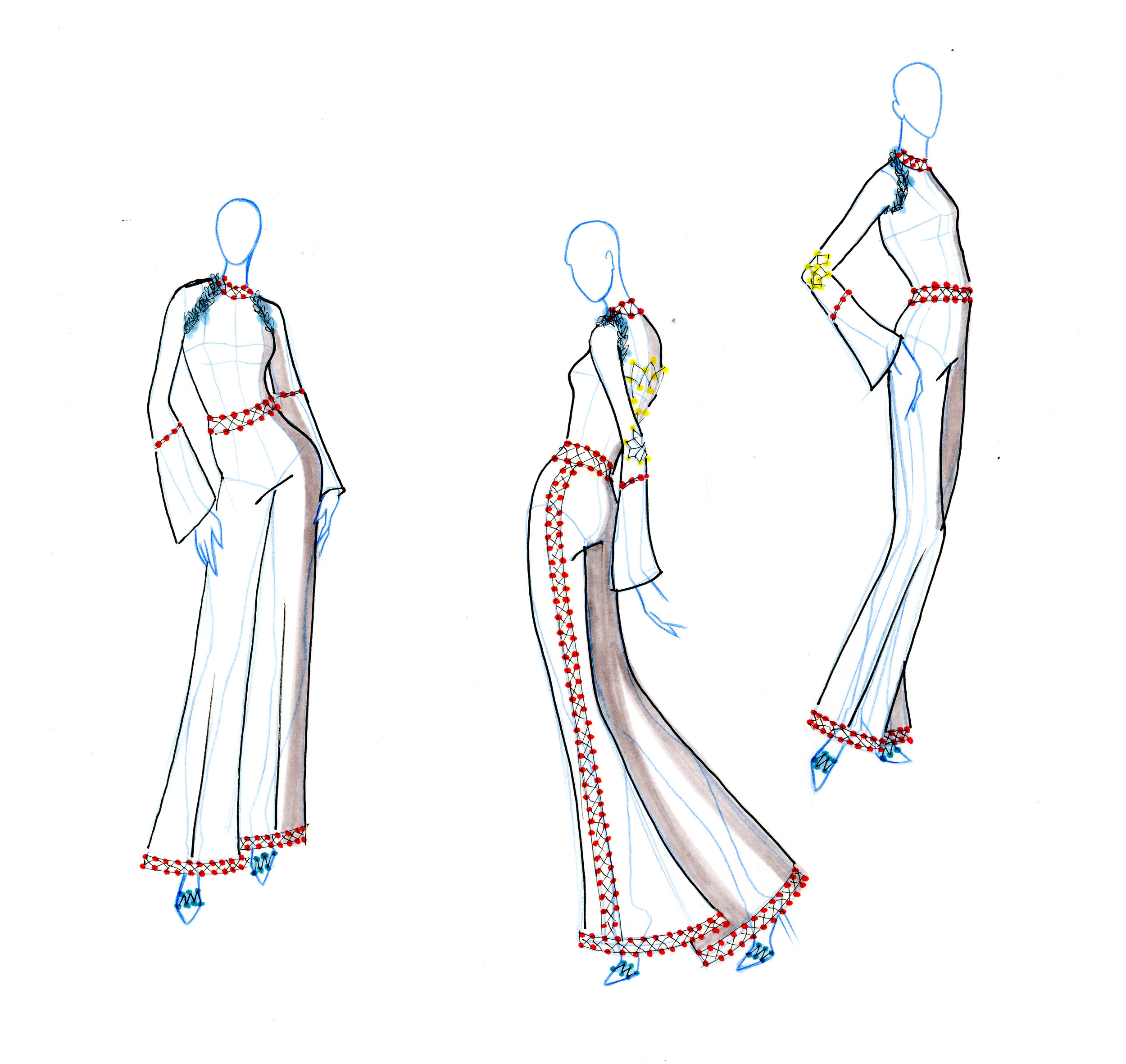

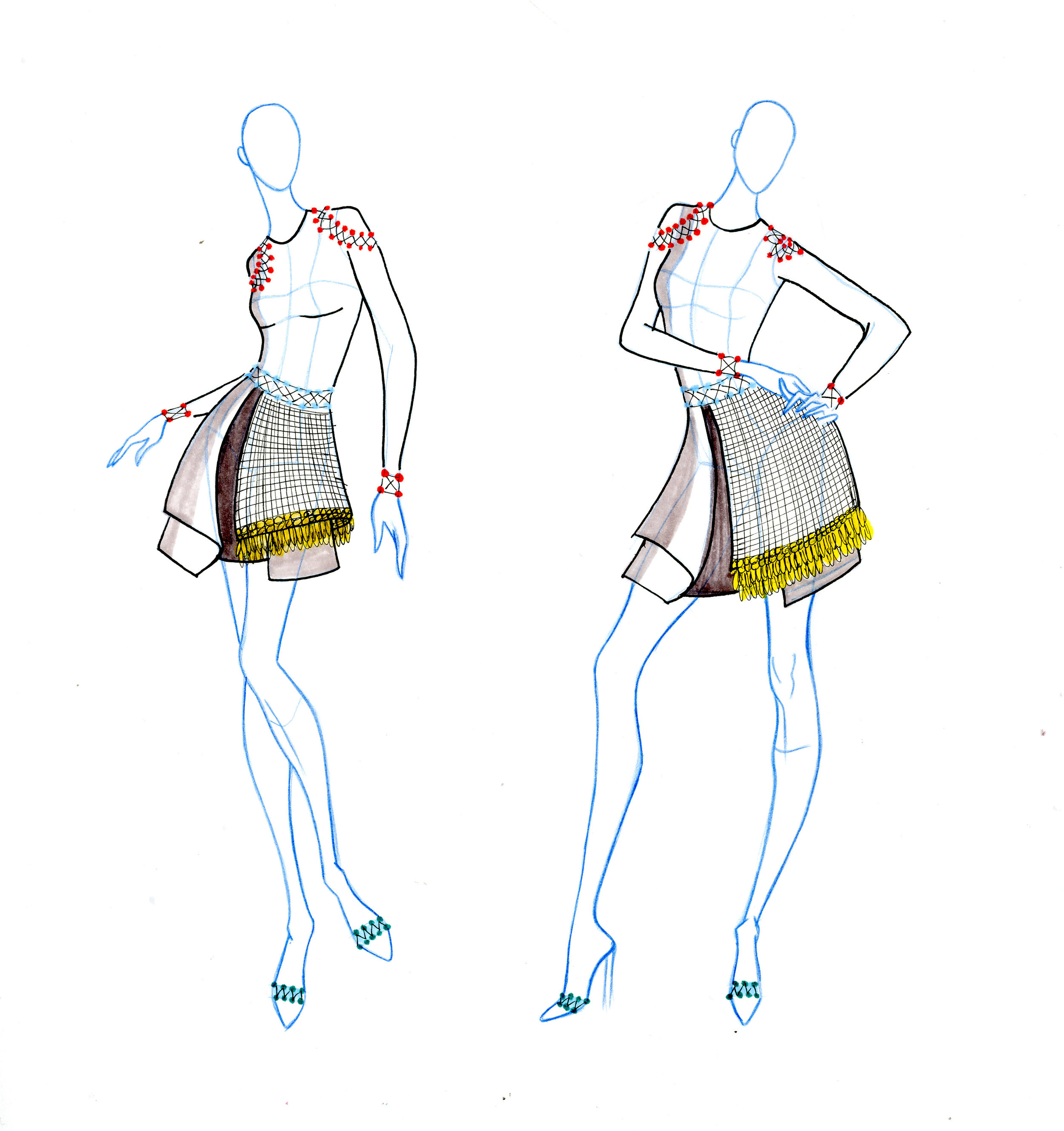

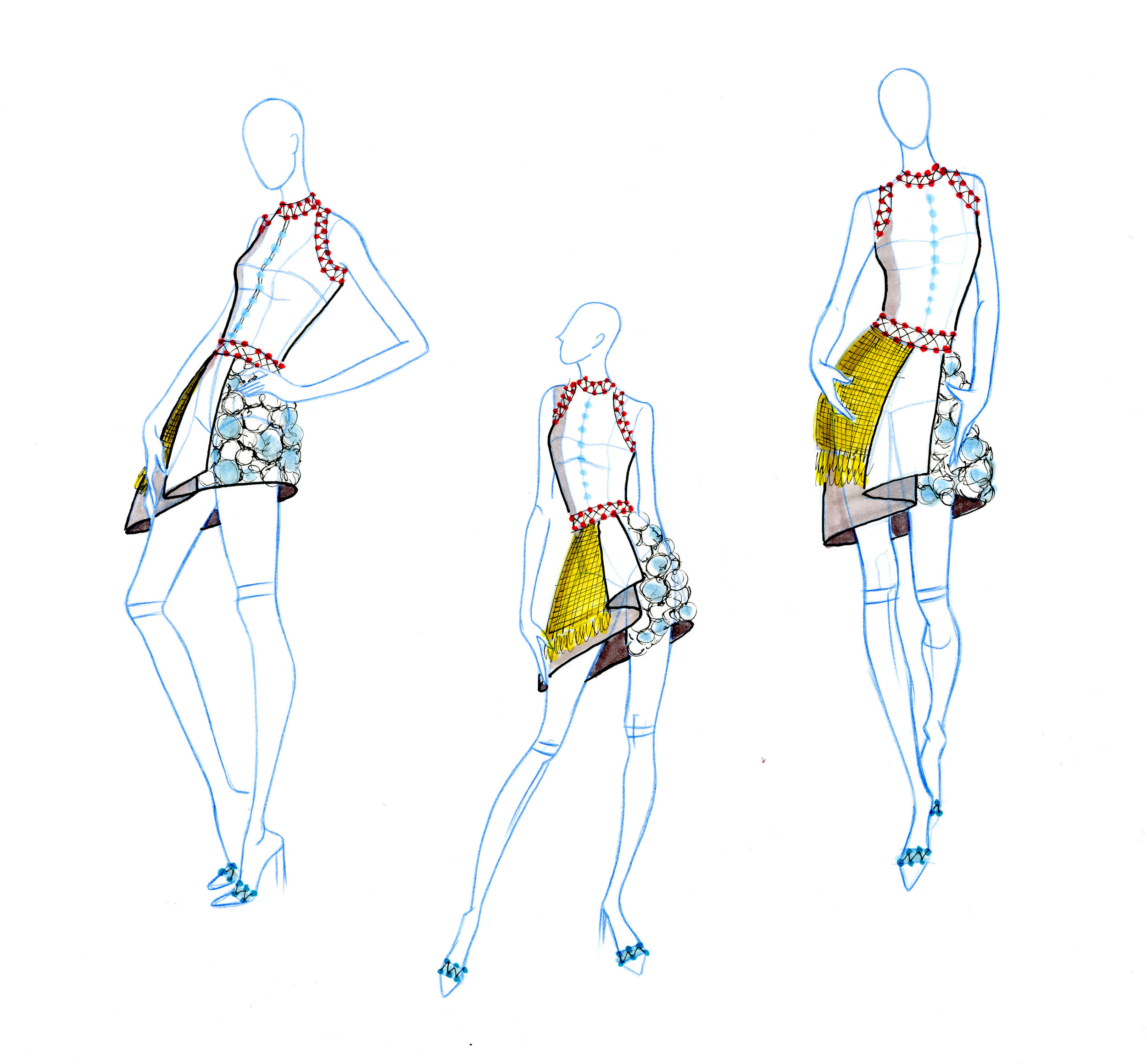

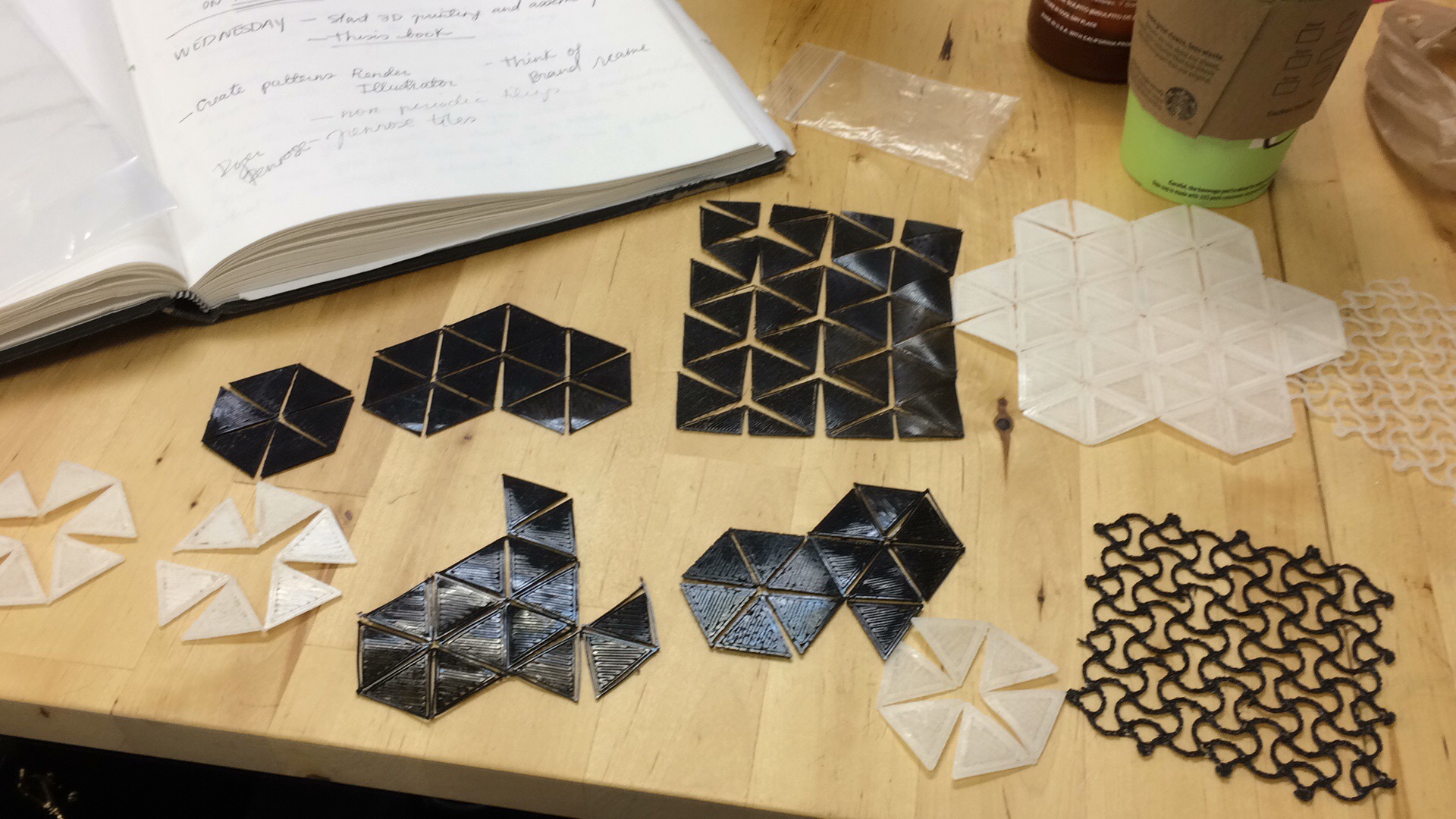

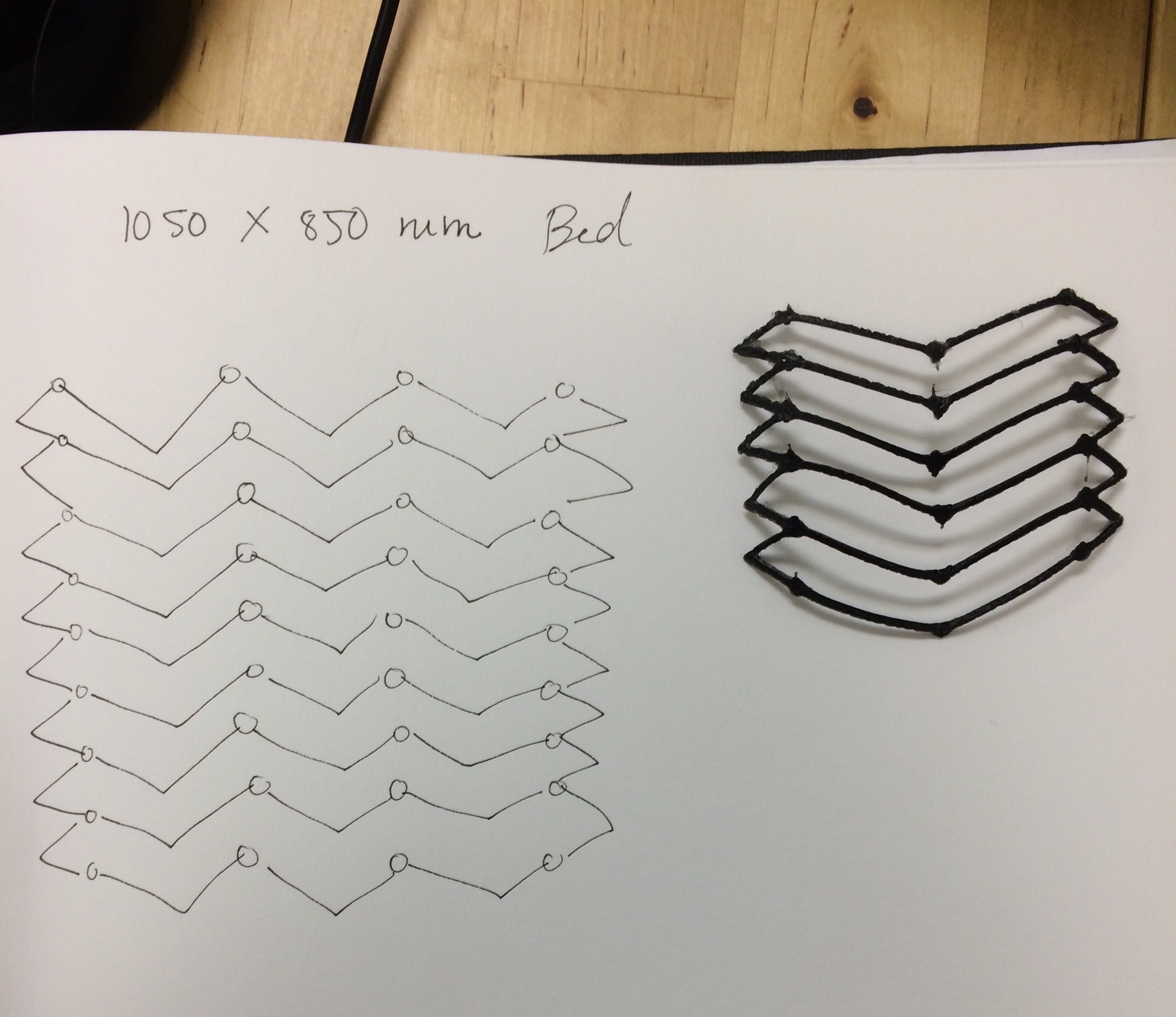

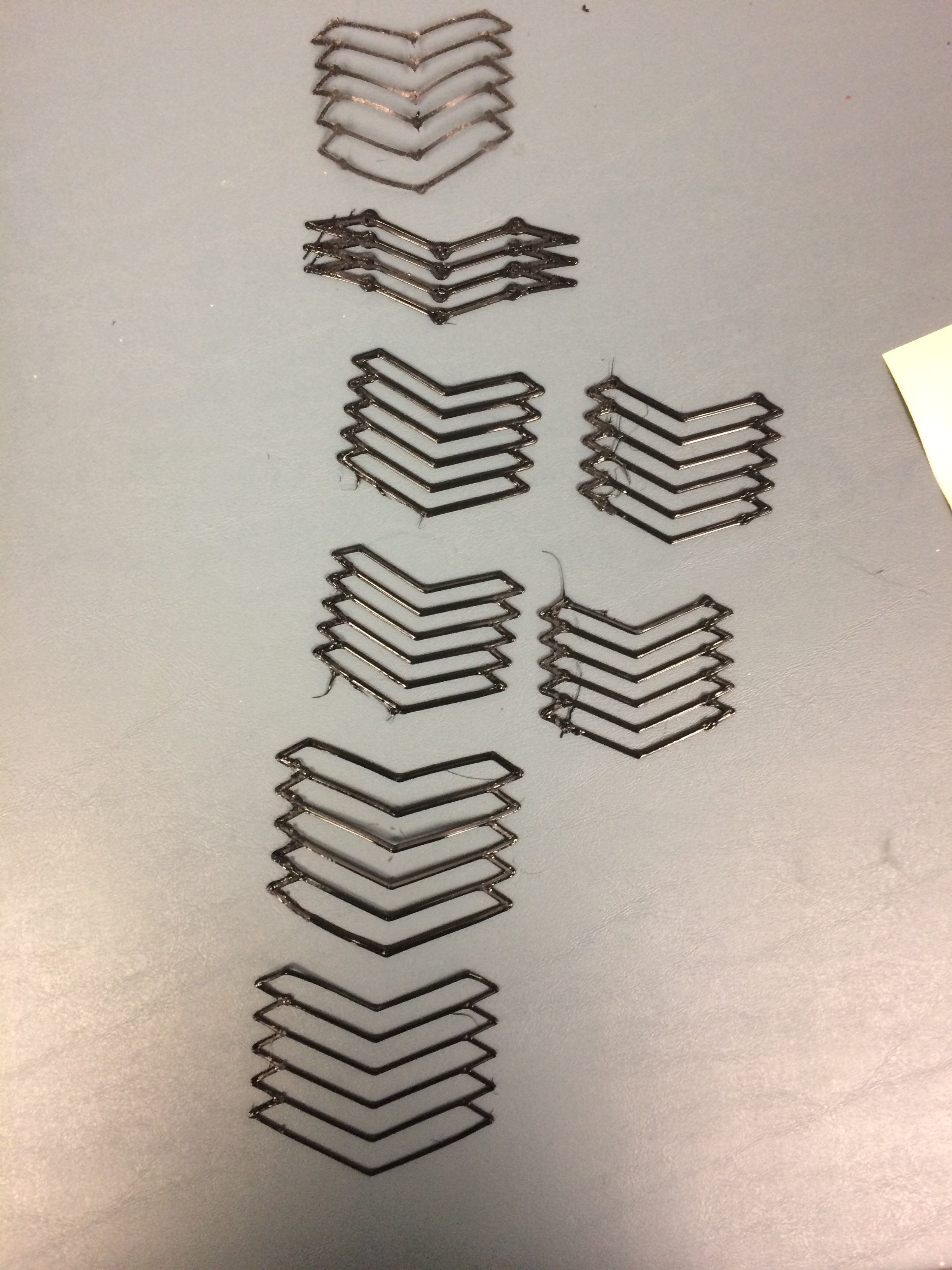

EARLY CONCEPTS

Studies - Renders - Sketches

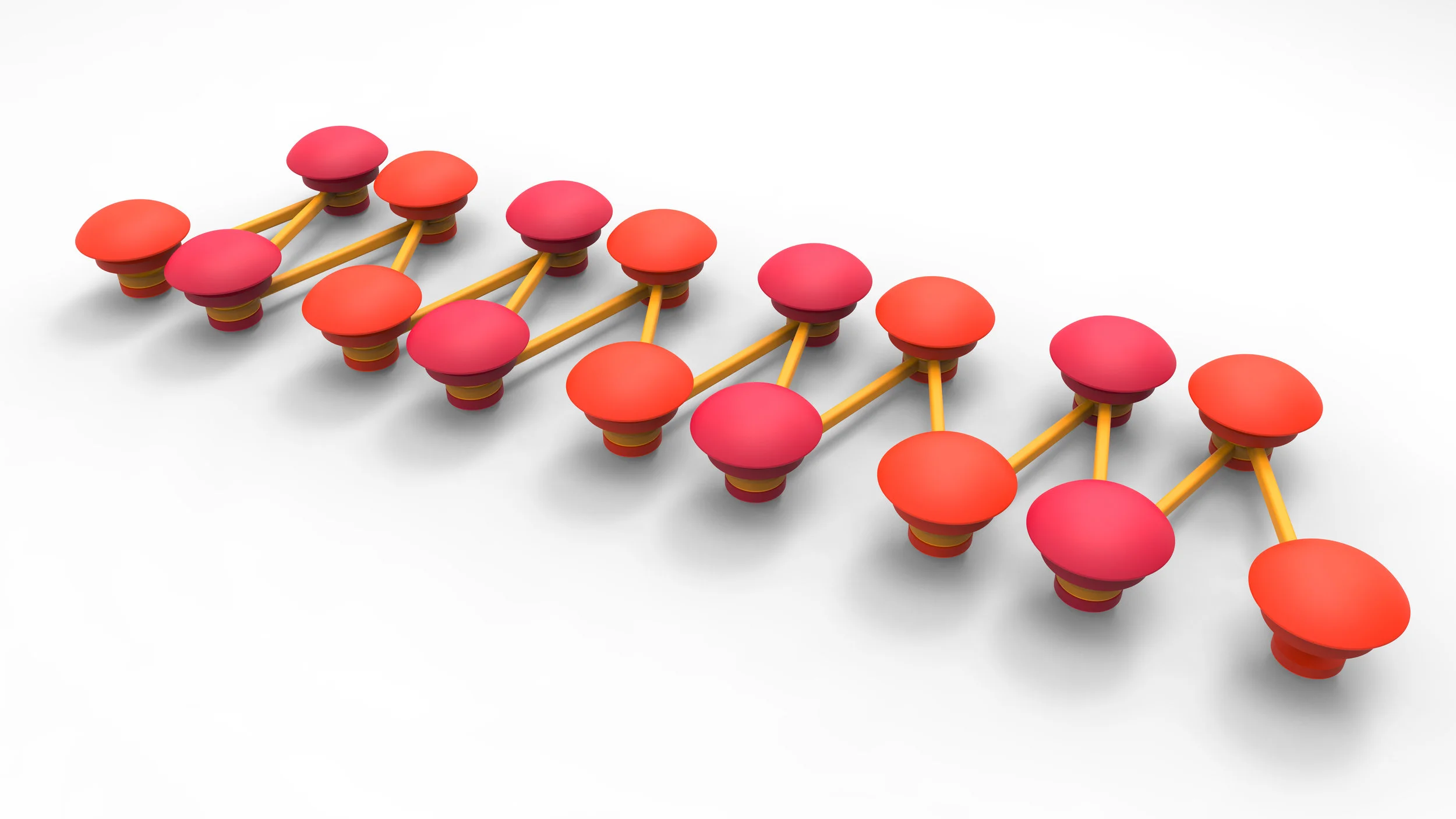

Mechanical Components & Fabric Weaving

- During this stage I realized that mechanical components weren't practical for wearables and that the functional mechanisms must be incorporated within the design integrity of the textile pattern.

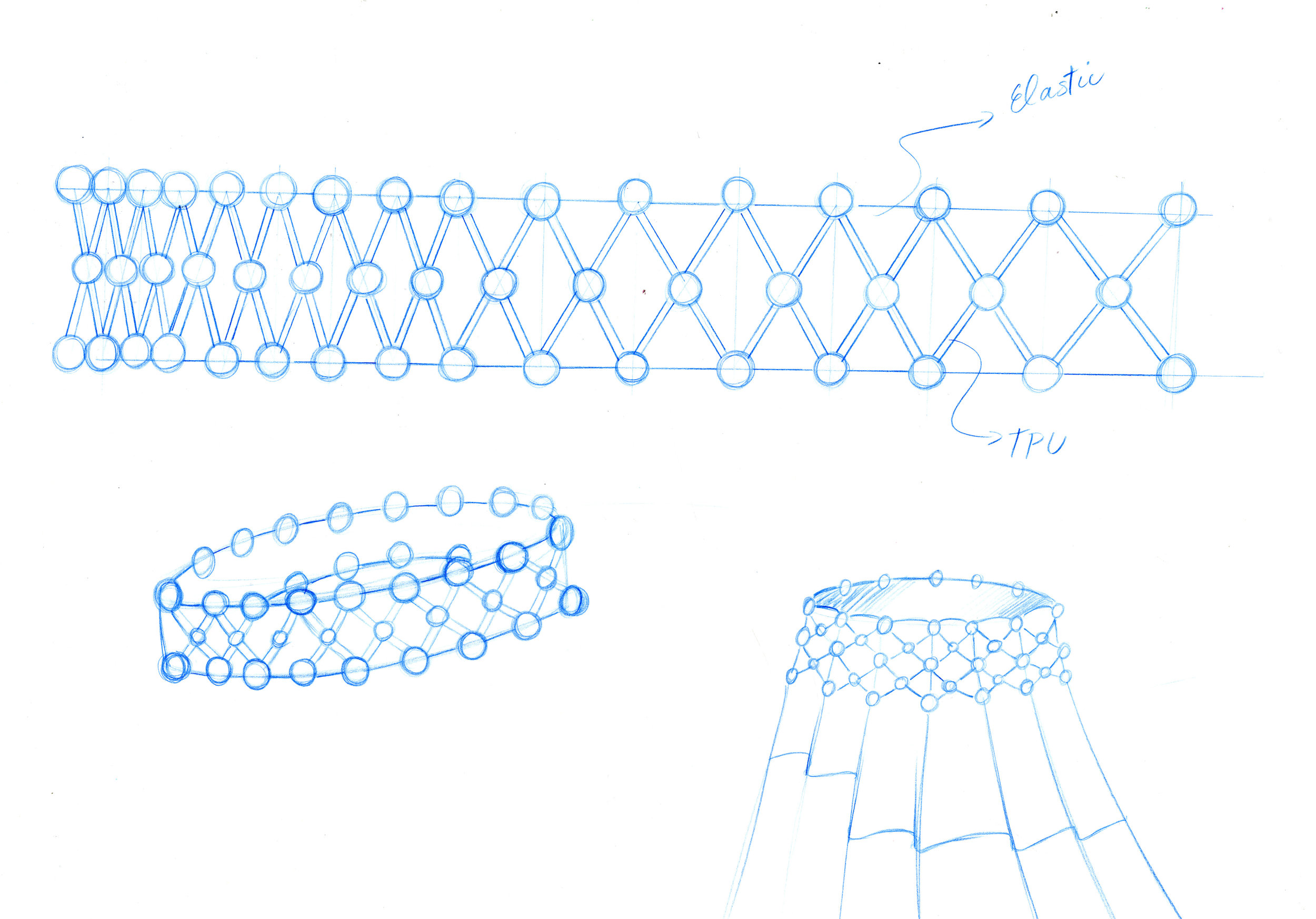

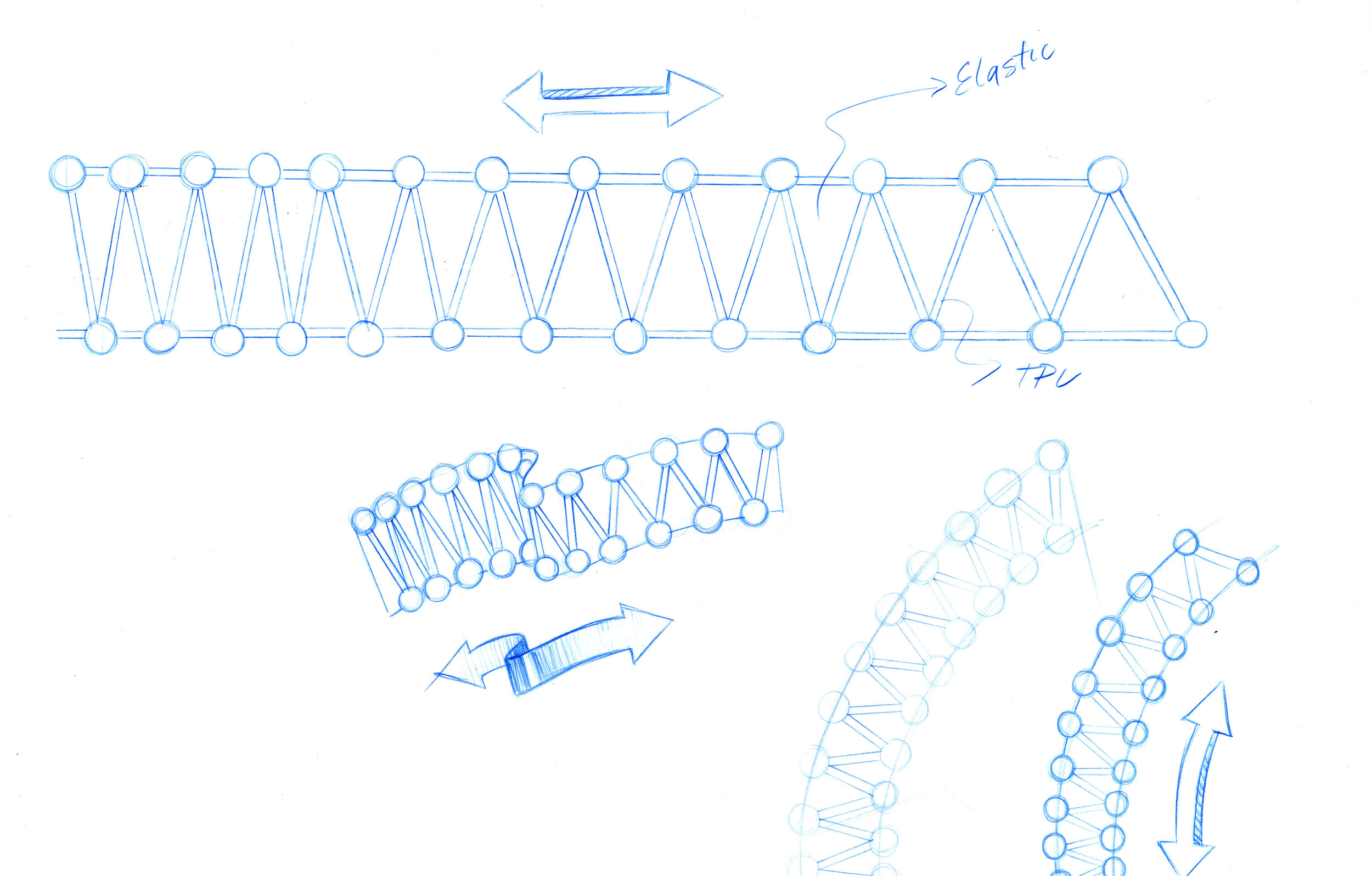

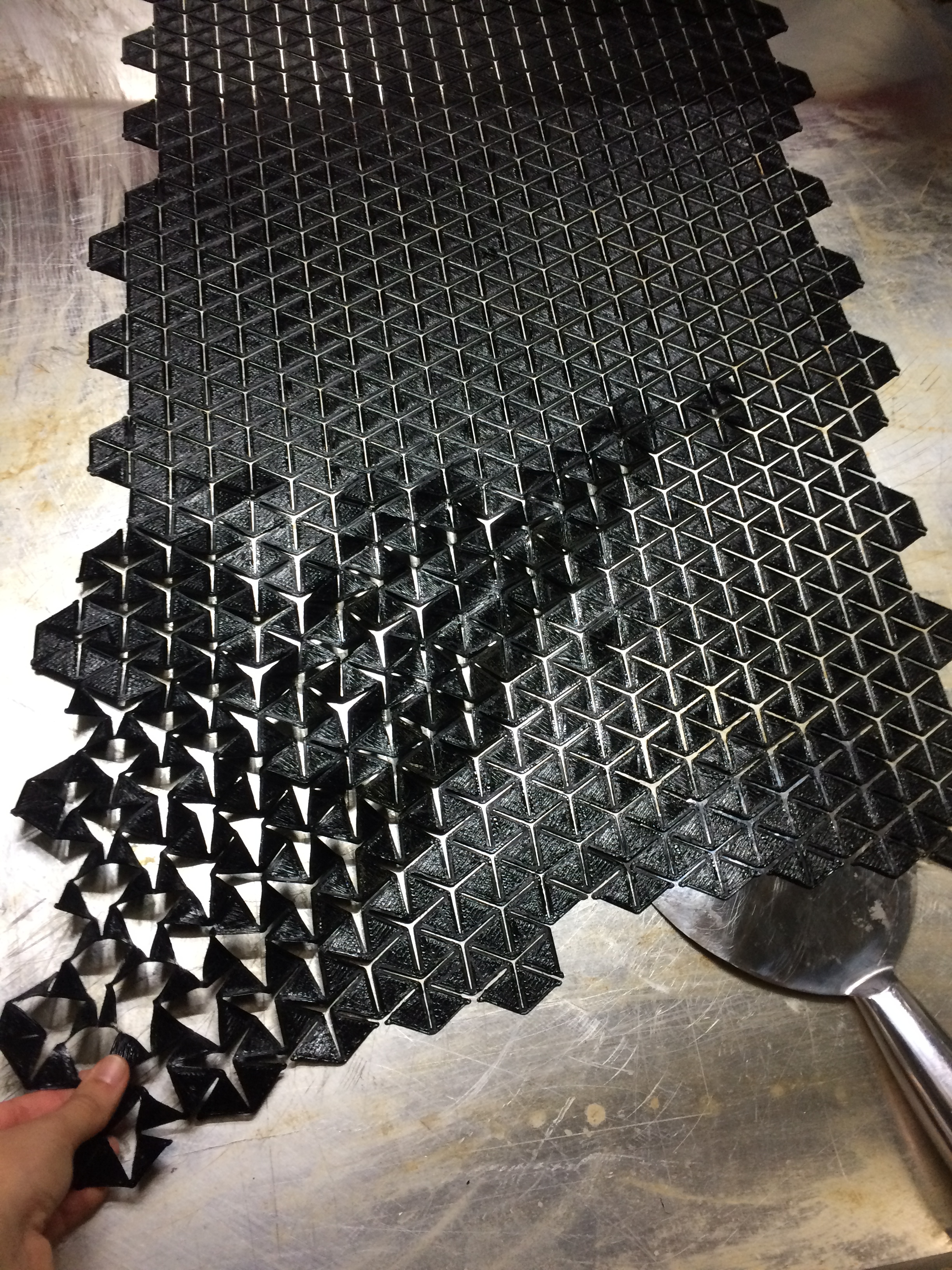

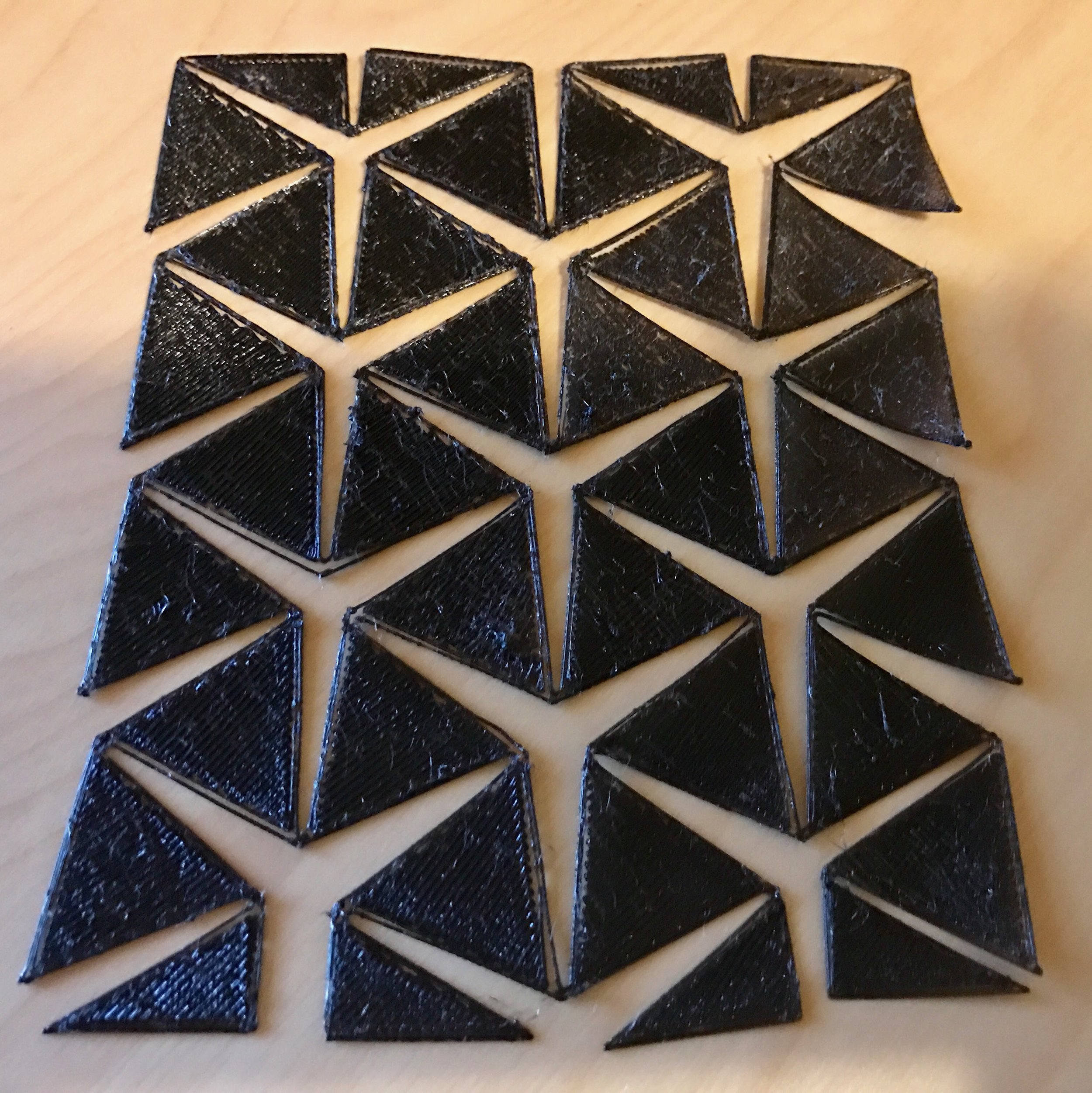

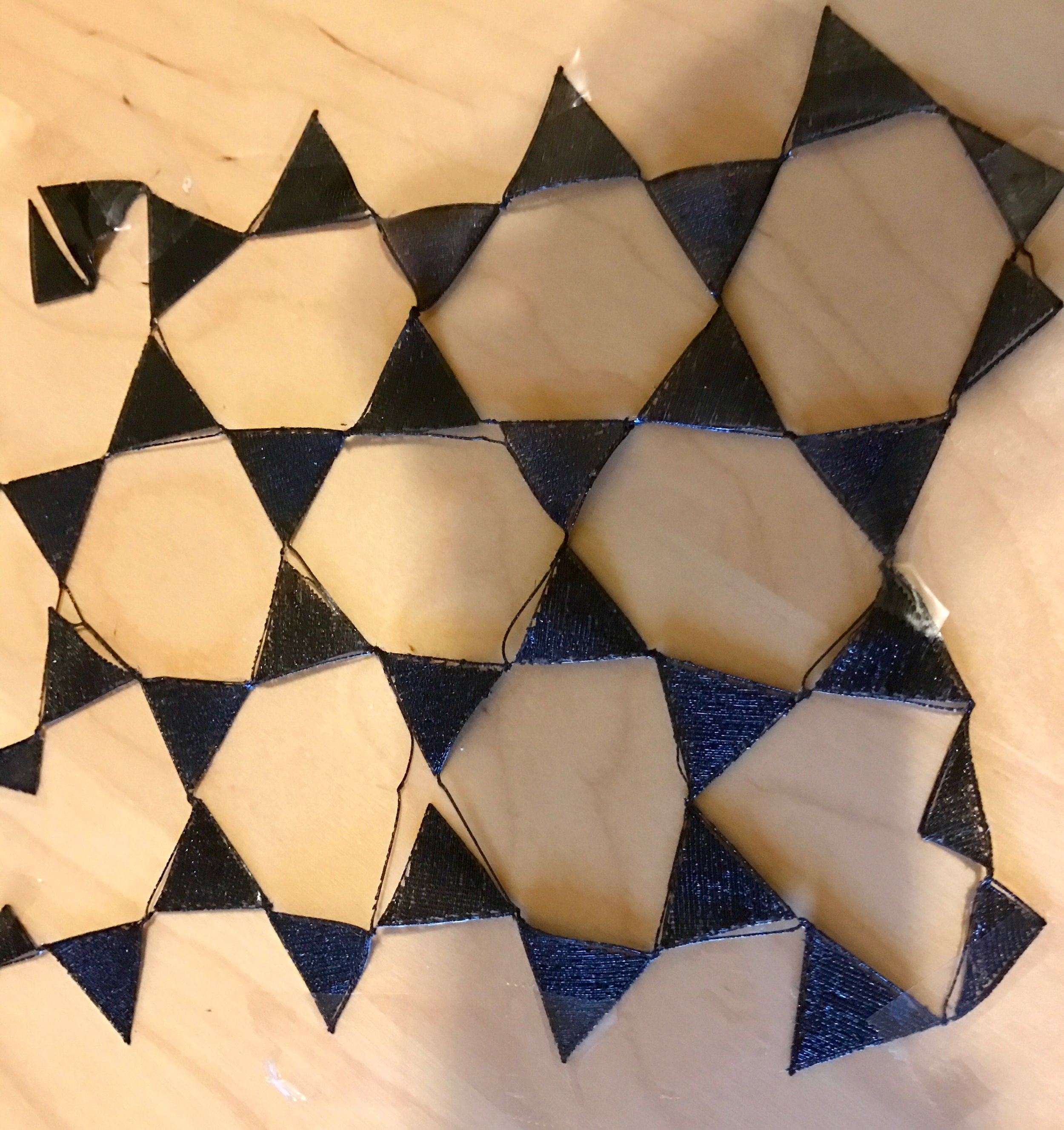

AUXETIC PATTERNS

the solution

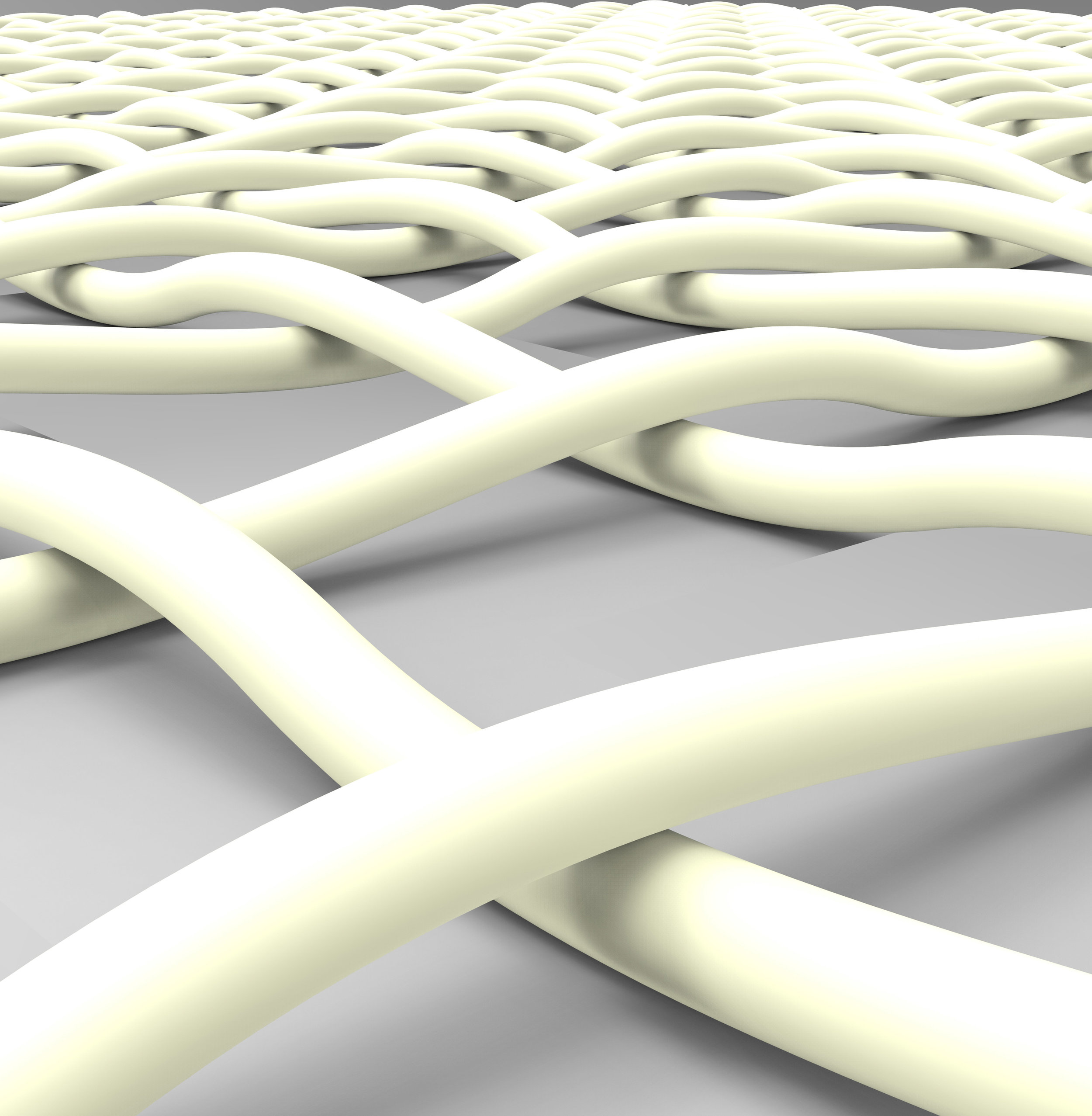

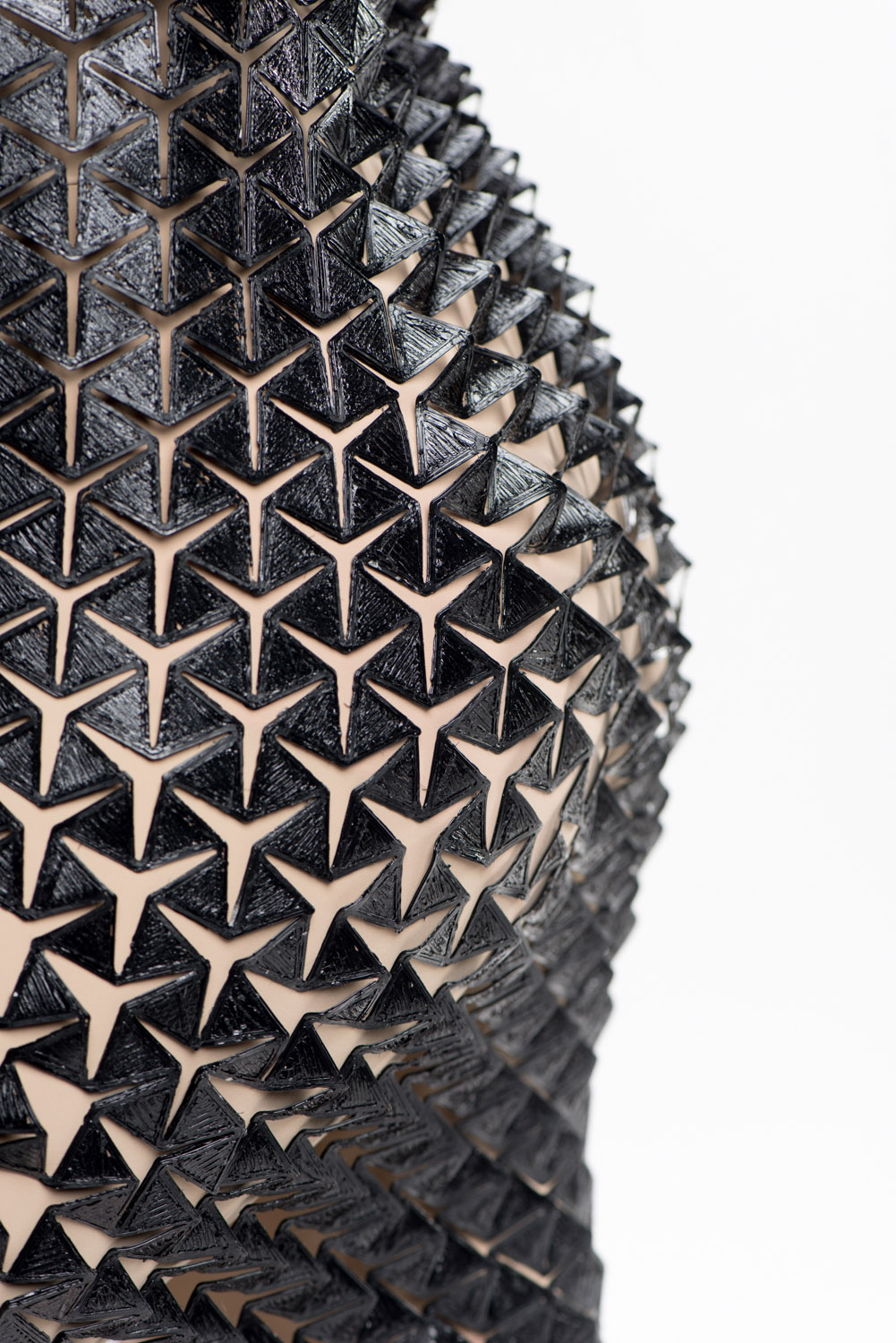

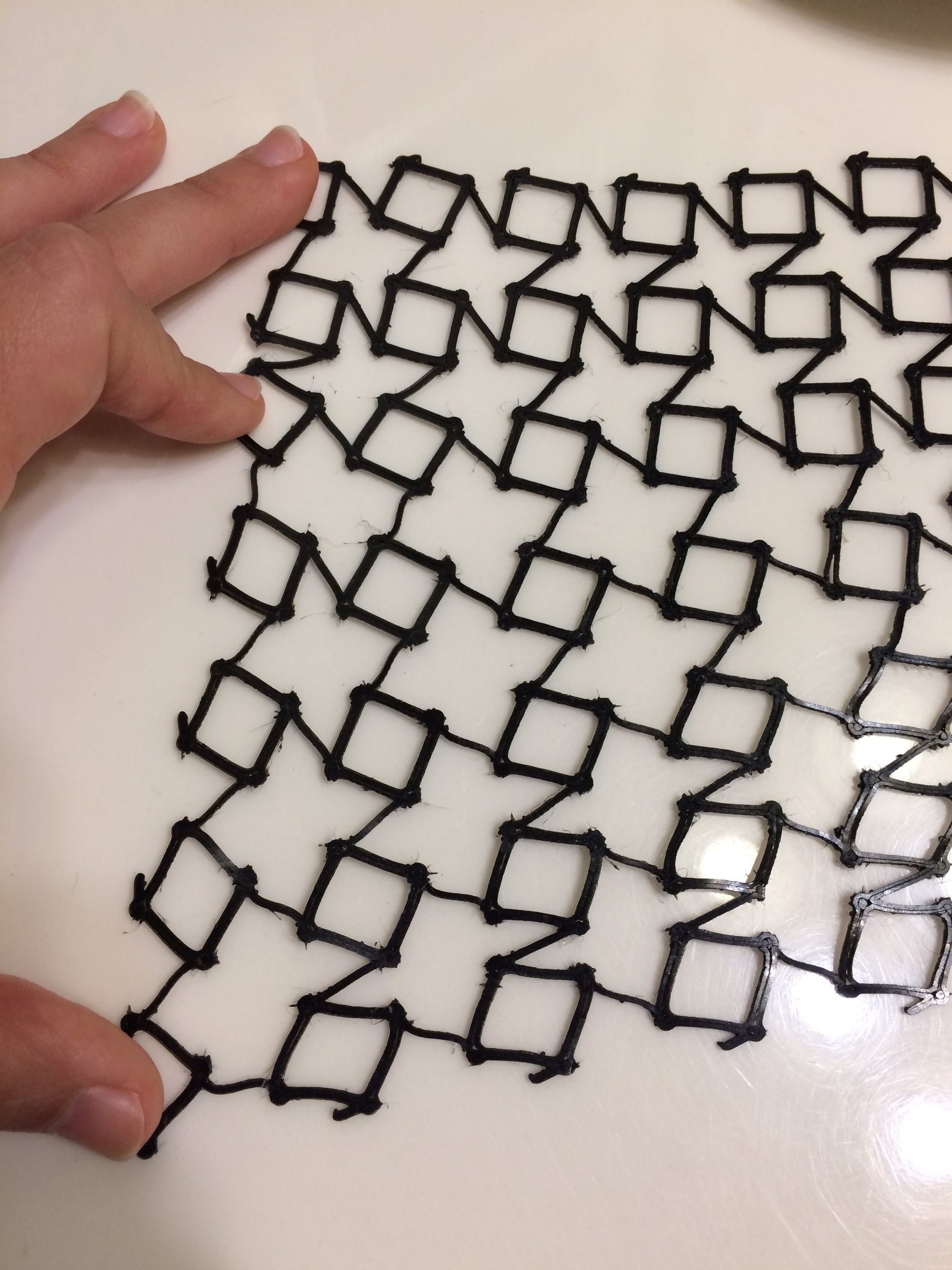

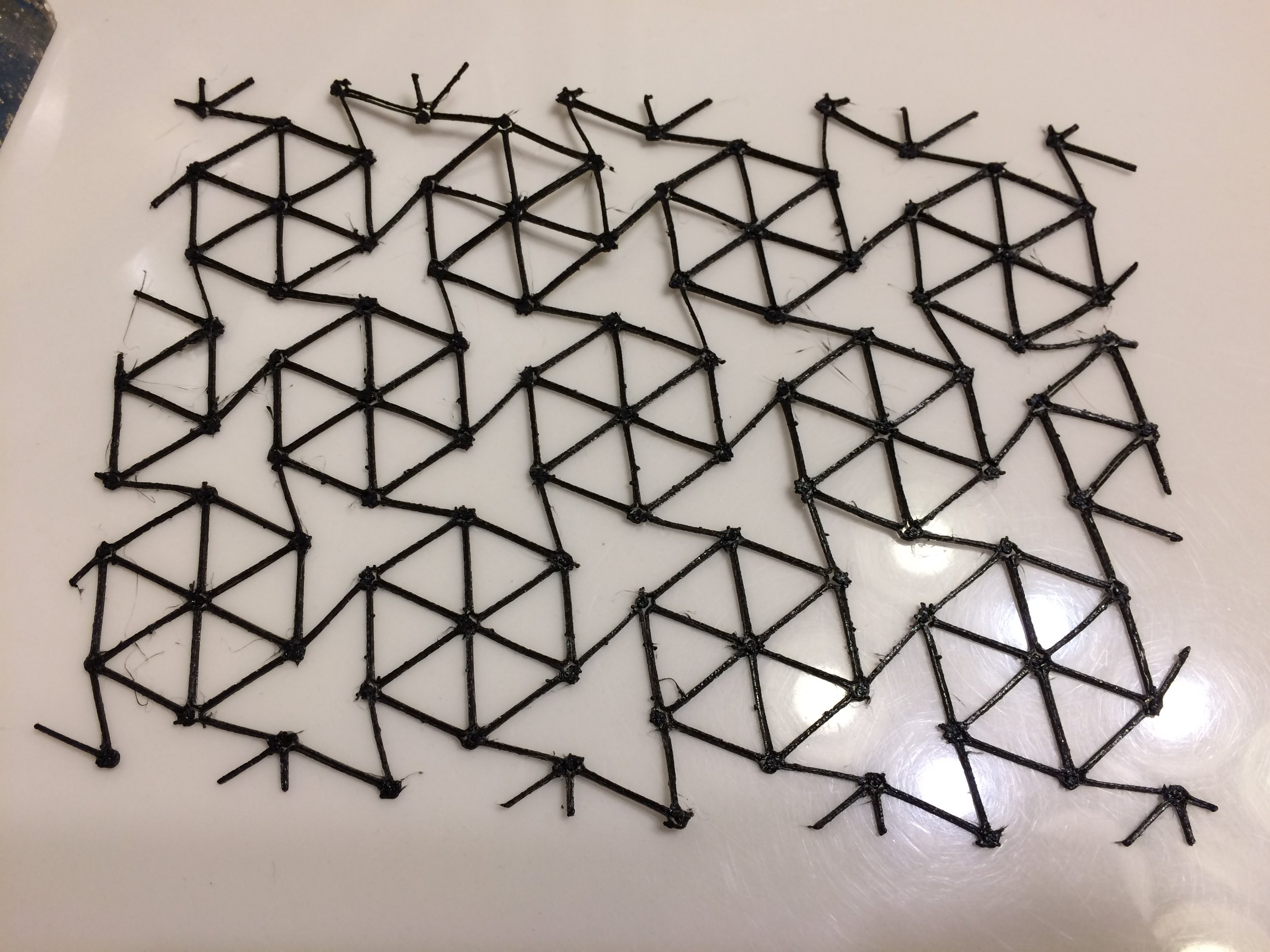

The collection explores ready-to-wear auxetic patterns which expand under longitudinal strain and contract when compressed.

- This behavior gives the swatches various beneficial effects compared to the current ones in the market.

- Their added value lies in form, function and the geometric arrangements of the patterns.

THERMOPLASTIC POLYURETHANE (TPU)

THE Material

TPU FILAMENT

BENEFITS

auxetic patterns

- Increased shear modulus.

- Improved indentation resistance.

- Enhanced plane strain fracture toughness.

- Improved energy absorption properties.

- Enable porosity/permeability variation with strain.

- Ability to form synclastic curvatures.

thermoplastic polyurethane

- High abrasion resistance.

- Low-temperature performance.

- High shear strength.

- High elasticity (500% elongation).

- Oil and grease resistance.

FFF VS SLS PRINTING

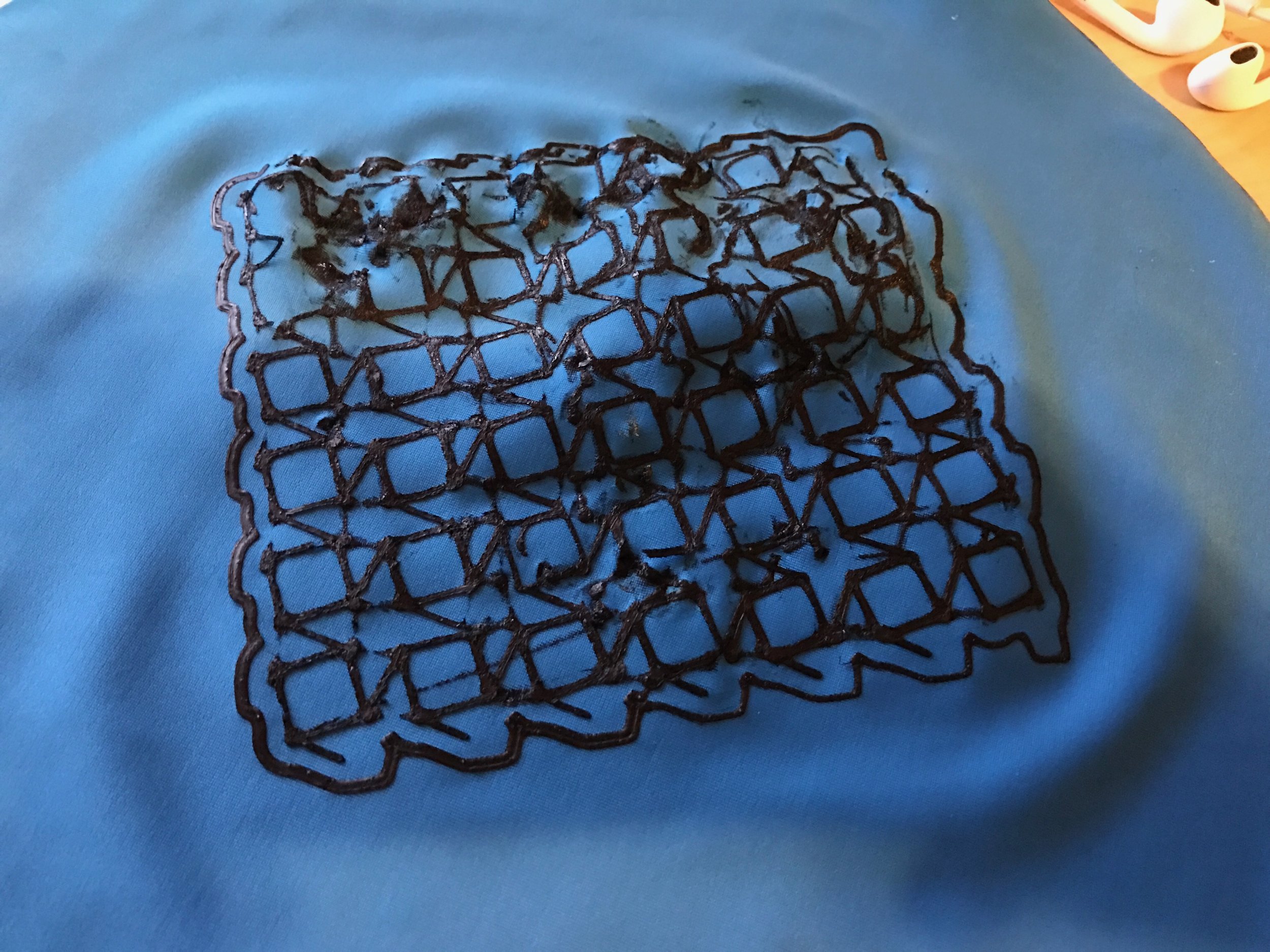

- My initial method of fabrication was SLS printing. After analyzing the pros and cons between both I decided FFF would be the best option for this project.

TEXTILE COLLECTION

Adapts to body changes and body types

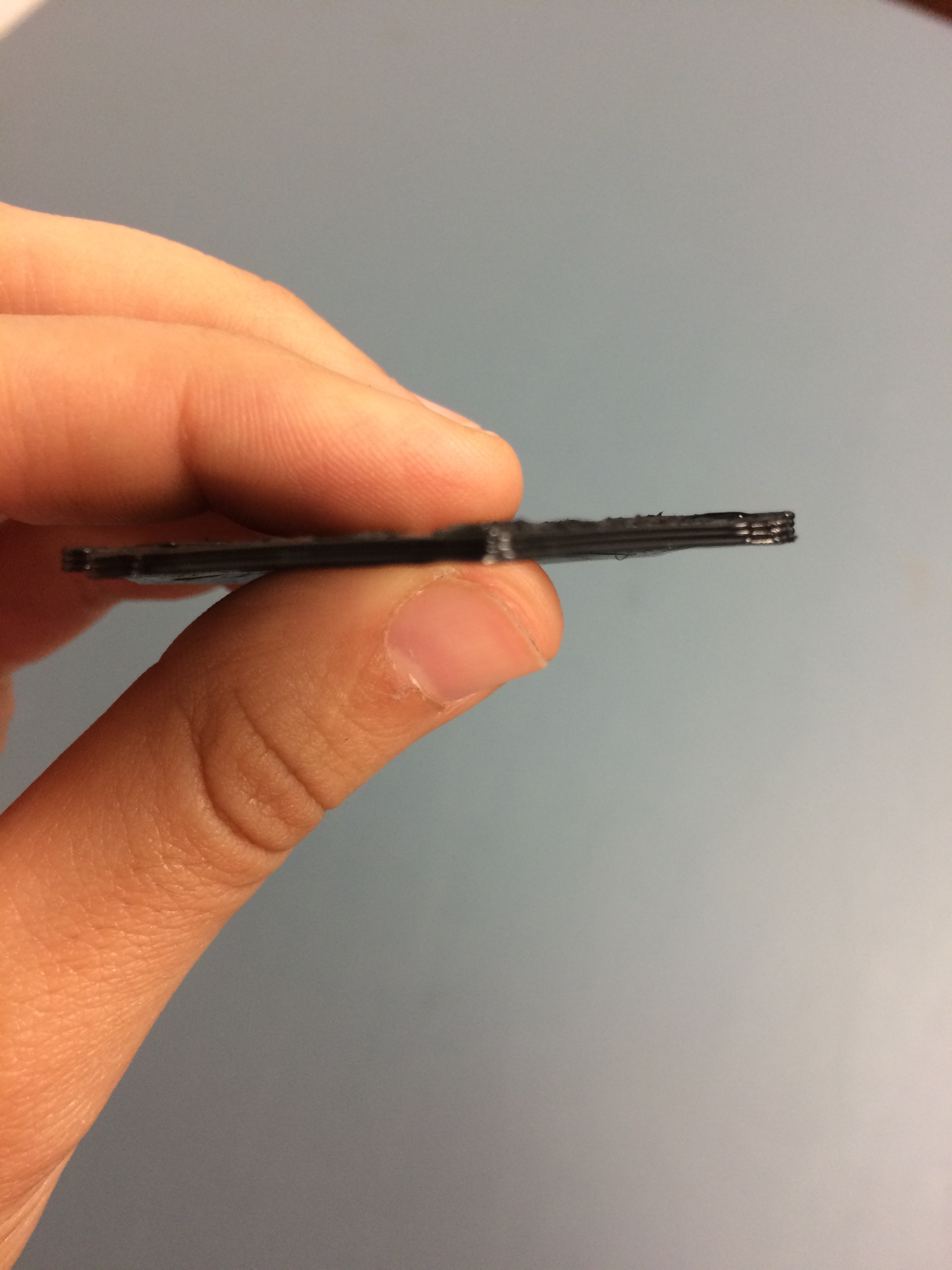

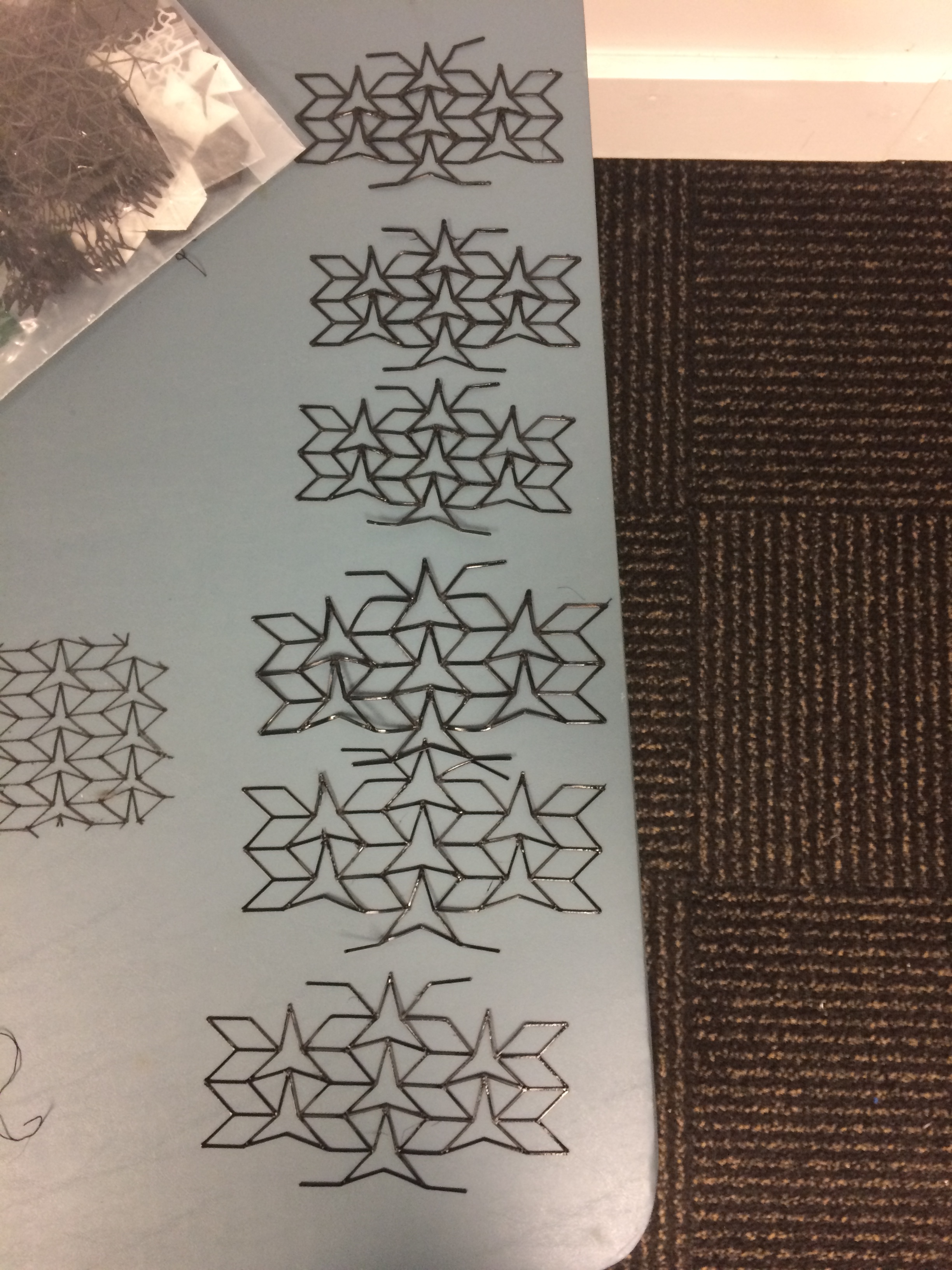

PROTOTYPING

MATERIAL Testing

Nylon - Ninja Flex - TPU

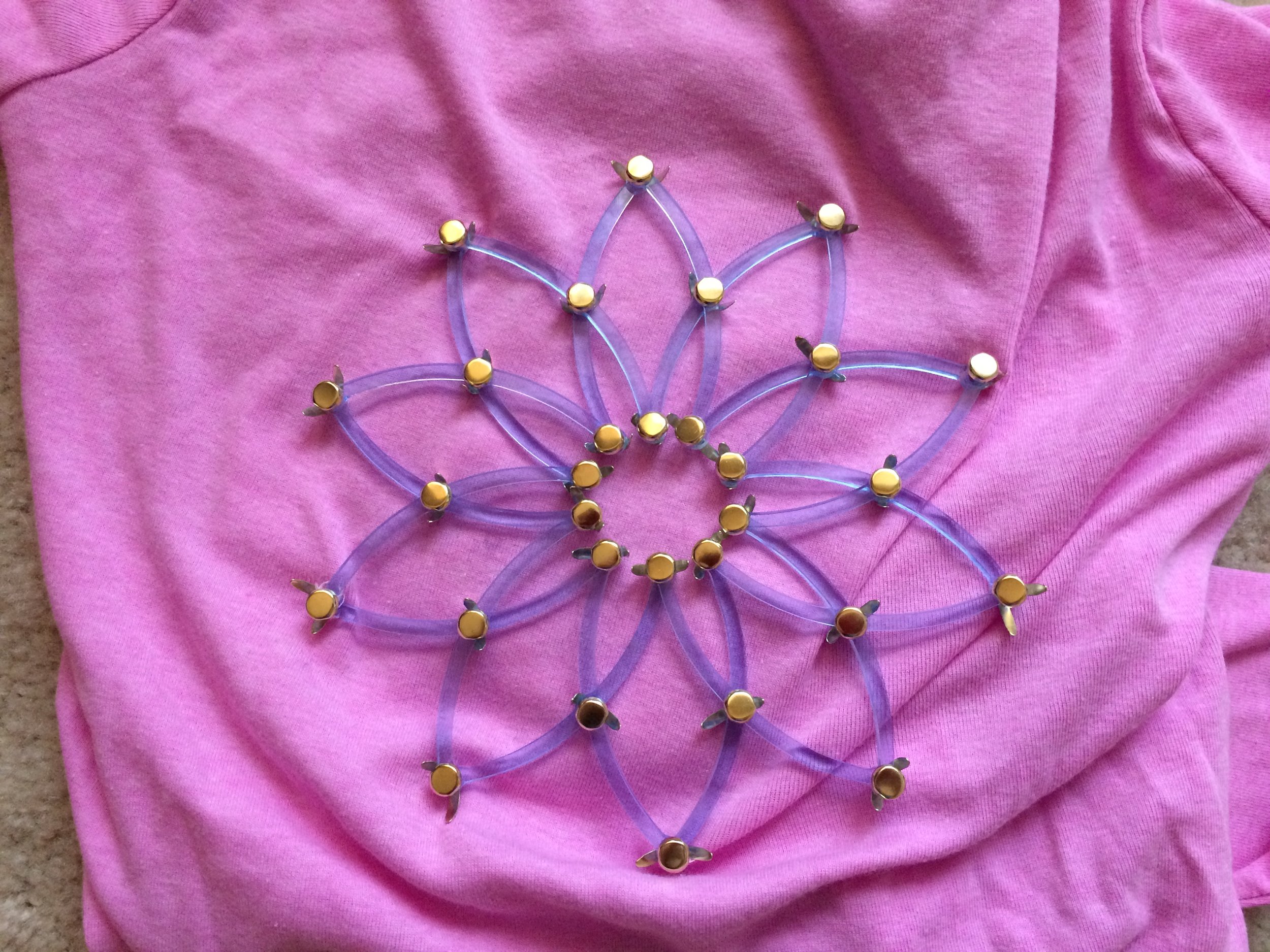

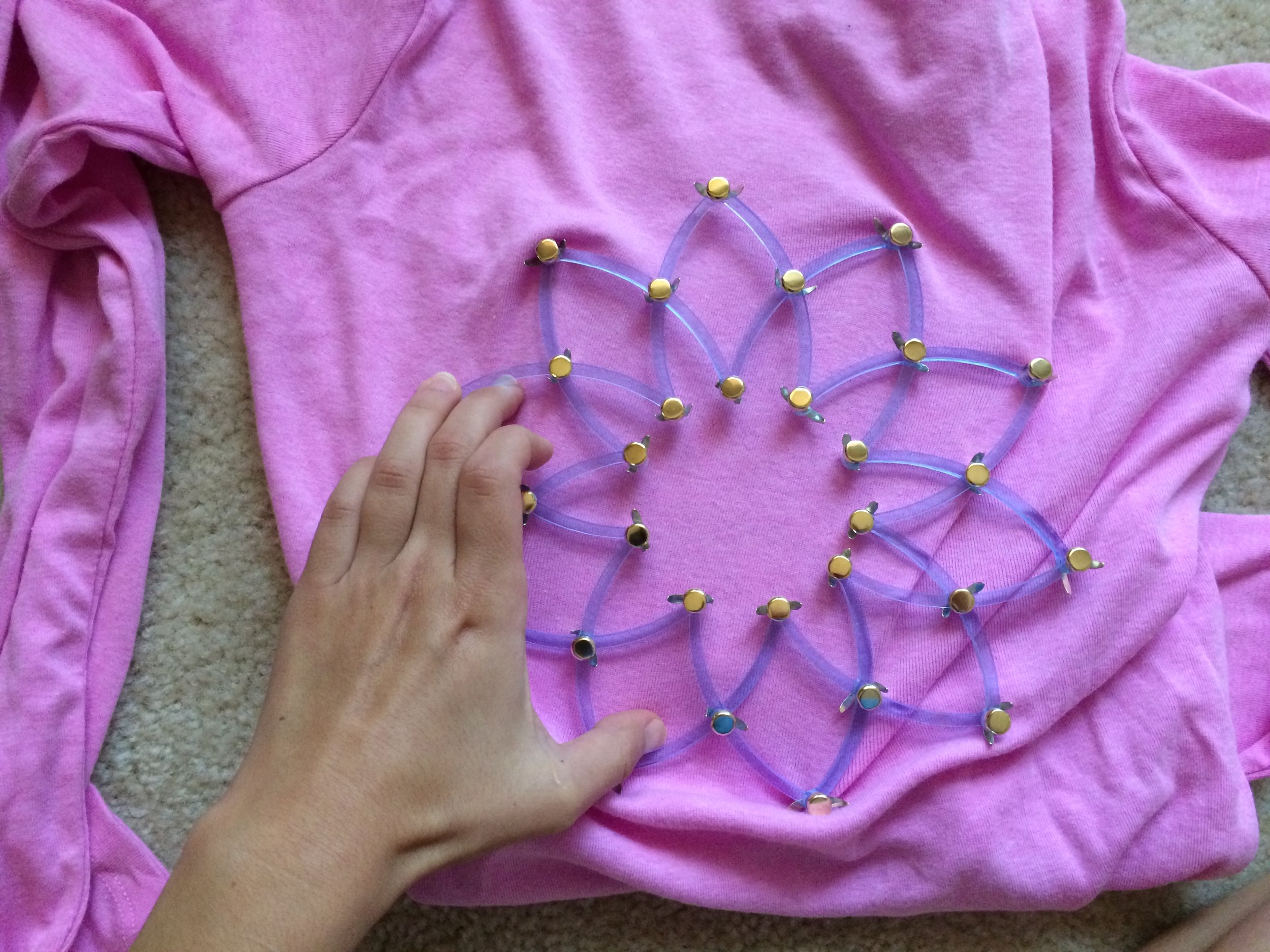

- We tested different materials to see how the patterns behaved and attempted to print the patterns on stretchy fabric.

- Testing took the most time and effort, but through each failure we became closer to our final TPU settings.

REFINE

FASHION COLLECTION

FINAL SKETCHES

EXECUTE

Look no. 2 | Pattern 6

LOOM

final dress

- Loom is an expandable, adaptable, wearable and flexible 3D printed dress. It combines textiles and additive manufacturing by applying materials and auxetic structures that consider function and the human body.

Re-Invent Materials

With the print time cut in half, testing new materials is faster and cheaper than ever. Learn more about materials testing possibilities with our Pellet Feed System from our CTO and co-founder, Andrew McCalip, in the video below.

Meet Cosine's CTO and co-founder, Andrew McCalip as he explains the different possibilities with the pellet feed system on the Cosine AM1.

Contact us to talk to a Pellet Feed Expert today.

Cosine at the Advanced Manufacturing Expo

Come see Cosine at booth 210 at the Advanced Manufacturing Expo happening in Grand Rapids, MI on August 24, 2017. Cosine's CEO and co-founder, Jason Miller, and our Director of Technical Support and Customer Service, Jacob Jacobson, will be there to showcase our recent developments on our AM1.

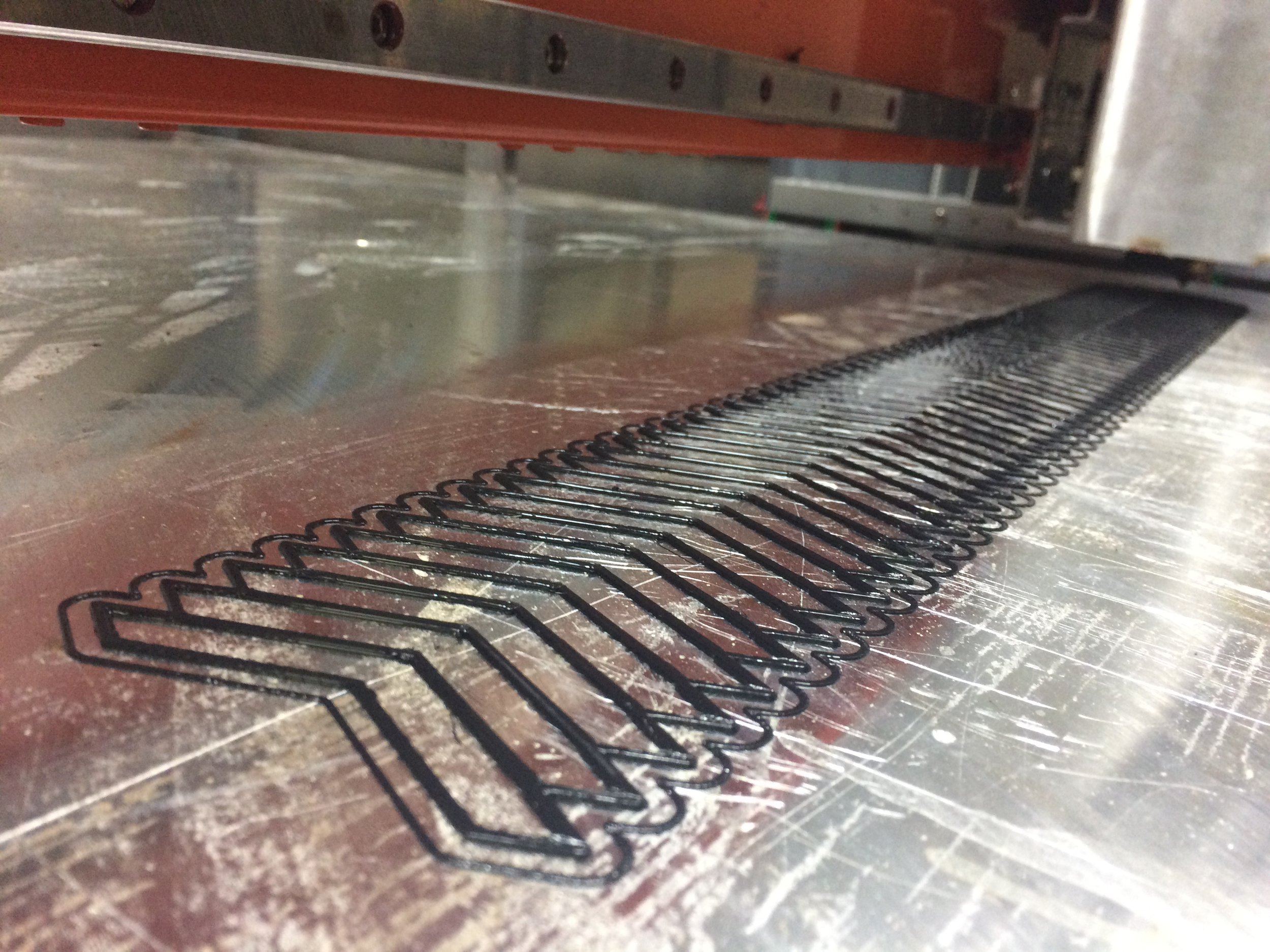

Printing with 50% carbon fiber PPS

Our pellet feed system is making moves! Printing 50% carbon fiber Techmer Electrafil PPS with ease! Testing with our pellet feed system gets easier and easier every time. To learn more about the pellet feed system read our blog post all about it here.

Watch the video below to see our pellet feed in action with 50% carbon fiber infill pellets.

- Tensile Strength: 19.0 KSI

- Flexural Strength: 32.0 KSI

- Flexural Modulus: 5.4 MSI

Contact us to get your project started today!

About the AM1

Our customers love the Cosine Additive Machine 1 (AM1). Here's a quick introduction to the machine and its capabilities!

Have you seen our Youtube channel? Click here for more videos like this.

Introducing the Pellet Feed System

10x Cheaper Material on Your AM1

After a year in development, Cosine is excited to release our Pellet Feed System and will begin manufacturing this product for the AM1. By switching to pellet, we are capable of running a wider variety of polymer resin systems at an increased deposition rate of up to 10 lbs/hr. Printing with pellets is 10x faster and 10x cheaper than printing with filament. Existing customers can extend the capabilities of their AM1 by upgrading to the Pellet Feed System. Contact us to get your Pellet Feed System today.

Cosine at the Additive Manufacturing for Defense and Government

Geoff Nordloh, CFO, Cosine Additive

gnordloh@cosineadditive.com

YOU'RE INVITED

Meet Cosine at The Additive Manufacturing for Defense and Government in Washington, DC. Our CFO, Geoff Nordloh, will be there July 13-14. He will present our recentbreakthroughs, collaborations, and upgrades to our AM1 platform. Through our partnerships with NSWCC andOakridge National Lab (ORNL), we are expanding our reach into the government sector. Contact Geoff if you have any questions.

WE WORK WITH

GOVERNMENT BUYERS

Cosine already has established relationships with the SAIC. By the end of the year, our equipment and services will be obtainable through the GSA Multiple Awards Schedule.

Oarkridge signing August 2016

CREATING BONDS WITH CRADA

We’re collaborating with Oakridge National Lab (ORNL) and NSWCC to develop new technologies and improve methods in the 3D printing industry with our Cosine AM1.

In these projects:

NSWCC requested improved data collection, and Cosine's solution was to develop and install a new bleeding edge motion system .

ORNL requested to develop a new pellet feed system. Cosine delivered a pellet extruder capable of printing 10 lbs/hr, allowing for a higher deposition rate and cost reduction with our open material platform.

Trim Tool Case Study

Complex surface geometries can mandate expensive and time consuming tooling solutions. Traditional solutions include CNC machining and composite tooling. Machined tooling is a trade space between raw material costs and CNC capacity. Offloading tooling work from heavily burdened CNC’s can open up capacity for higher value products. Composite tooling requires a series of pattern tools and back up structures(plywood crates or welded tubular frames) that can induce a variety of challenges. These processes can result in increased expenses, long lead times, consume valuable resources (CNC machine time), and families of patterns that need to be tracked and maintained in addition to the tools themselves.

Additive manufacturing enables users to create complex geometries from a variety of tough thermal polymers. Solid models are used to fabricate complex geometries directly, without the need for any secondary patterns. Often, the design rules for optimized additive manufactured tooling can be leveraged to provide ergonomic fixtures that simplify part processing and employ lower cost manufacturing solutions.

TRADITIONAL TOOLING

Fiberglass Splash Tool

• CAD/Reverse Engineer.

• Produce pattern for fiberglass layup

(CNC, splash or Egg Crate).

• Support frame fab.

• Fiberglass layup and frame integration.

• Finish tool (edge clean up].

Subtractive

Fiberglass Splash Tool

COSINE TOOLING

Cosine Manufactured Tool

Ready to Print

• Up to 1 lb/hour Material Deposition Rate.

• $8.40/hour Machine Utilization Cost (5yr amortization).

• $0.60/hour Electrical Cost.

Material Cost (choose one):

• $1/hour Base Polymer Pellet Material Cost.

• $8/hour Base/Neat Filamentized

Material Cost.

• $33/hour Filled Filamentized Polymer Material Cost.

Additive

Manufactured

Manufacturing Method Comparison

Cosine Machine Utilization Cost to Owners

Casting Industry Case Study

Current Methods

Traditional pattern methods are the most time consuming and complex processes in the casting industry.

LONG LEAD TIME

Long lead time due to materials and many complex steps.

160 HRS

HIGH COST

Expensive and

resource intensive

$5,000

SINGLE SHOT

30% of patterns received have mistakes and need to be reworked.

HIGHLY SKILLED LABOR

Skilled labor

Dying Trade

Cosine's Solution

The AM1 allows for faster, cheaper, and more efficient pattern creation.

28 HRS

SHORT LEAD TIME

Two day turn around.

$52

LOW COST

Total cost to make a

pattern with the AM1.

MULTIPLE ITERATIONS

Making revisions is as simple as hitting print.

GENERAL LABOR

Anyone can manufacture with the AM1’s intuitive quick-start process.

By using the Cosine AM1, your company can provide a rapid turn around for your customers, and save money over traditional pattern making techniques.

PATTERN CREATION TIMELINE

Traditional pattern making takes 4 weeks and costs an average of $5,000.

Cosine’s AM1 3D printer allows you to streamline your process with the least amount of hassle.

TAKE CONTROL OF YOUR PATTERN MANUFACTURING.

Contact us to receive a sample box and start your custom casting project.

We are ready to work with you!