QUICK TURNAROUND PATTERN MAKING

HOW 3D PRINTING EXPEDITES YOUR CASTING PROCESS

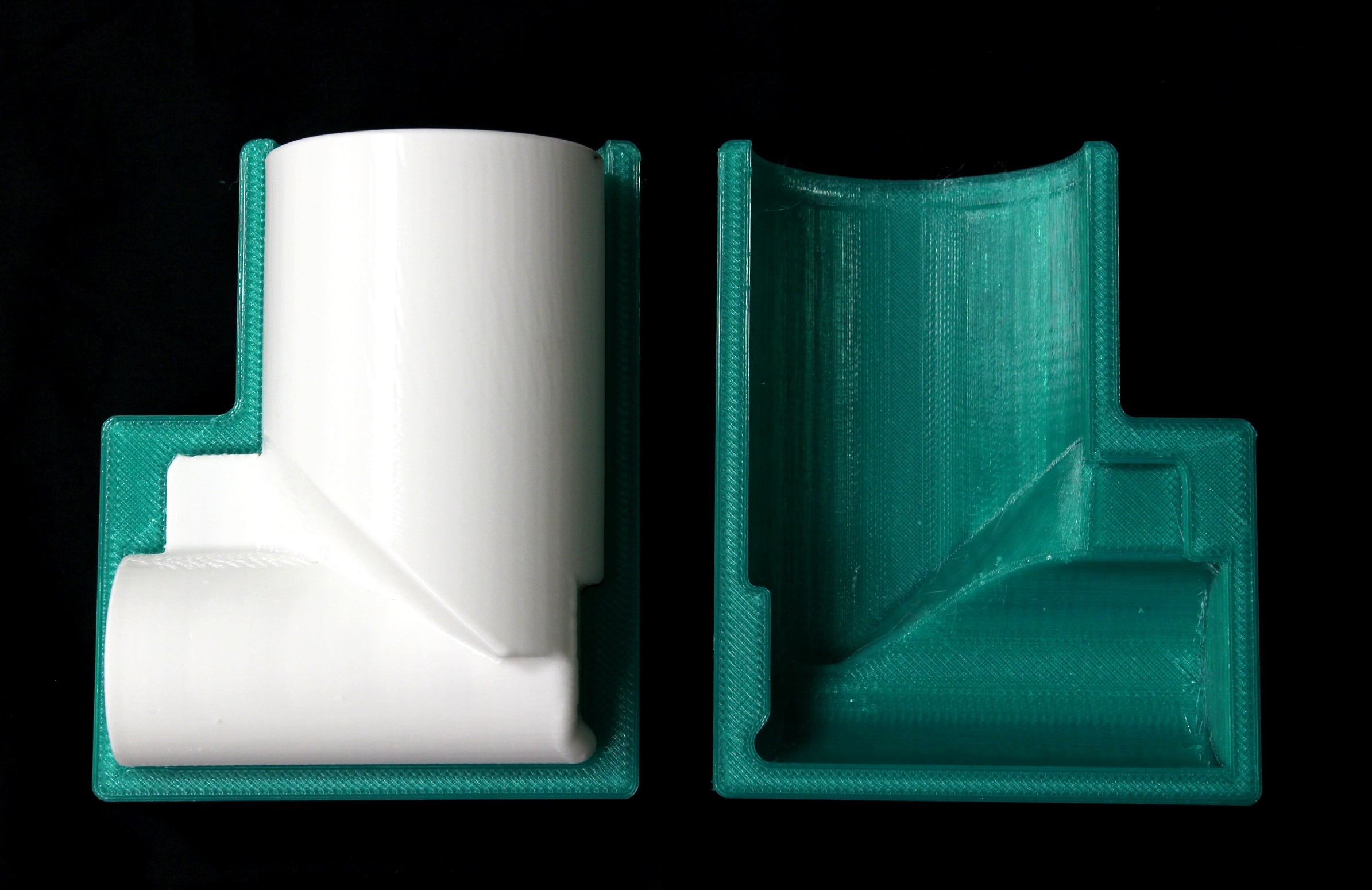

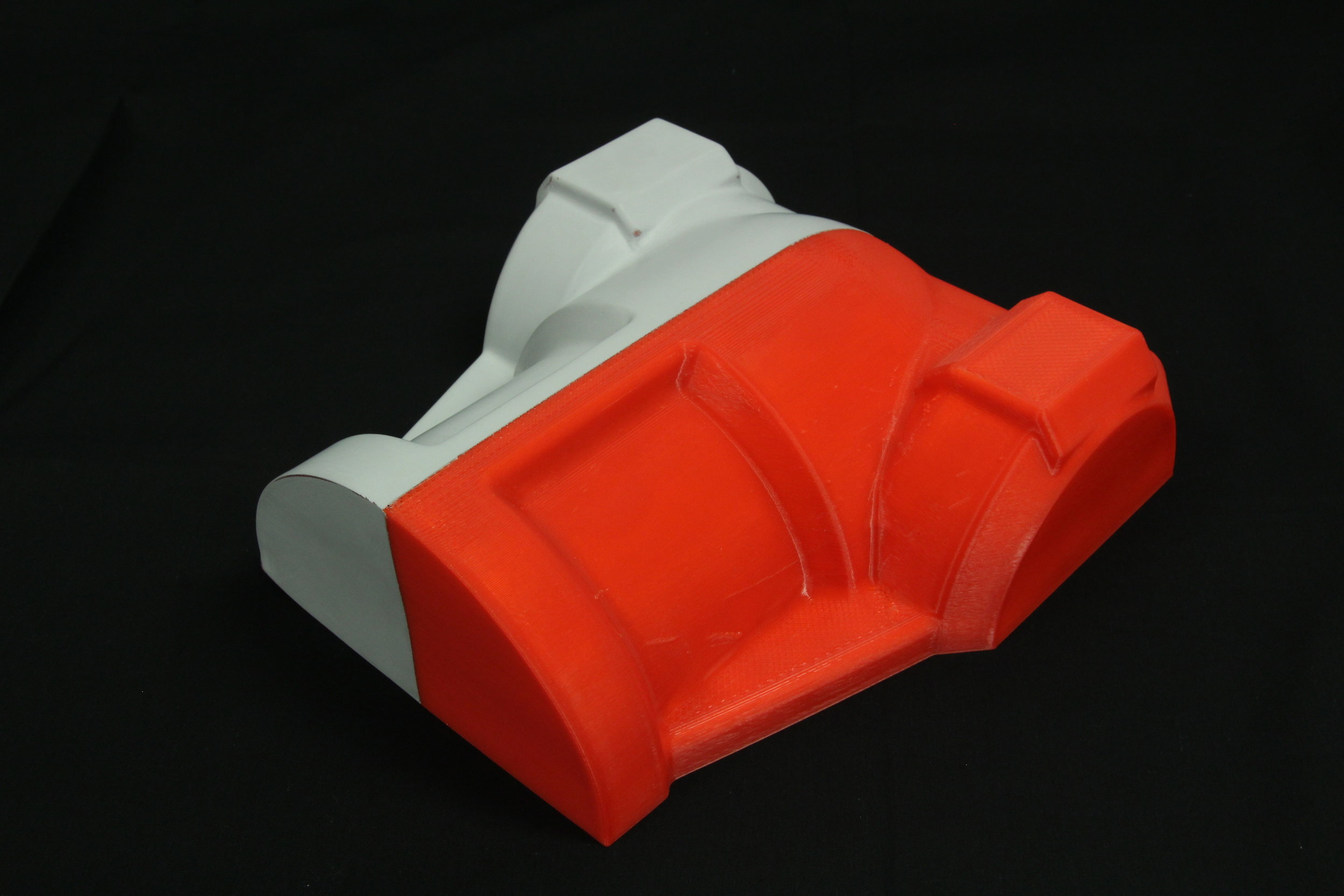

3D printing patterns is the perfect alternative for fast pattern making. With a wide range of different possible patterns, our AM1 is capable of providing that option. Creating wooden patterns and casting molds takes at least 4 weeks and costs an average of $5,000. However, our AM1 can provide a quick turnaround for pattern making. Working with Cosine allows you to streamline your process with the least amount of hassle.

Ask Our Customer

"Best service out of any 3D printer that I have ever experienced." - Kevin Kauphusman, Pattern Castings, Alliant Castings Alliant Castings has already run their Cosine AM1 for over 8,000 hours. Hear directly from one of our customers how 3D printing with the AM1 has changed the game in the casting industry.

Current Methods

Traditional pattern mold creation methods are the most time consuming and complex processes in the casting/foundry industry.

LONG LEAD TIME

Long lead time due to materials and many complex steps.

160 HRS

HIGH COST

Expensive and

resource intensive

$5,000

SINGLE SHOT

30% of patterns received have mistakes and need to be reworked.

HIGHLY SKILLED LABOR

Skilled labor

Dying Trade

Cosine's Solution

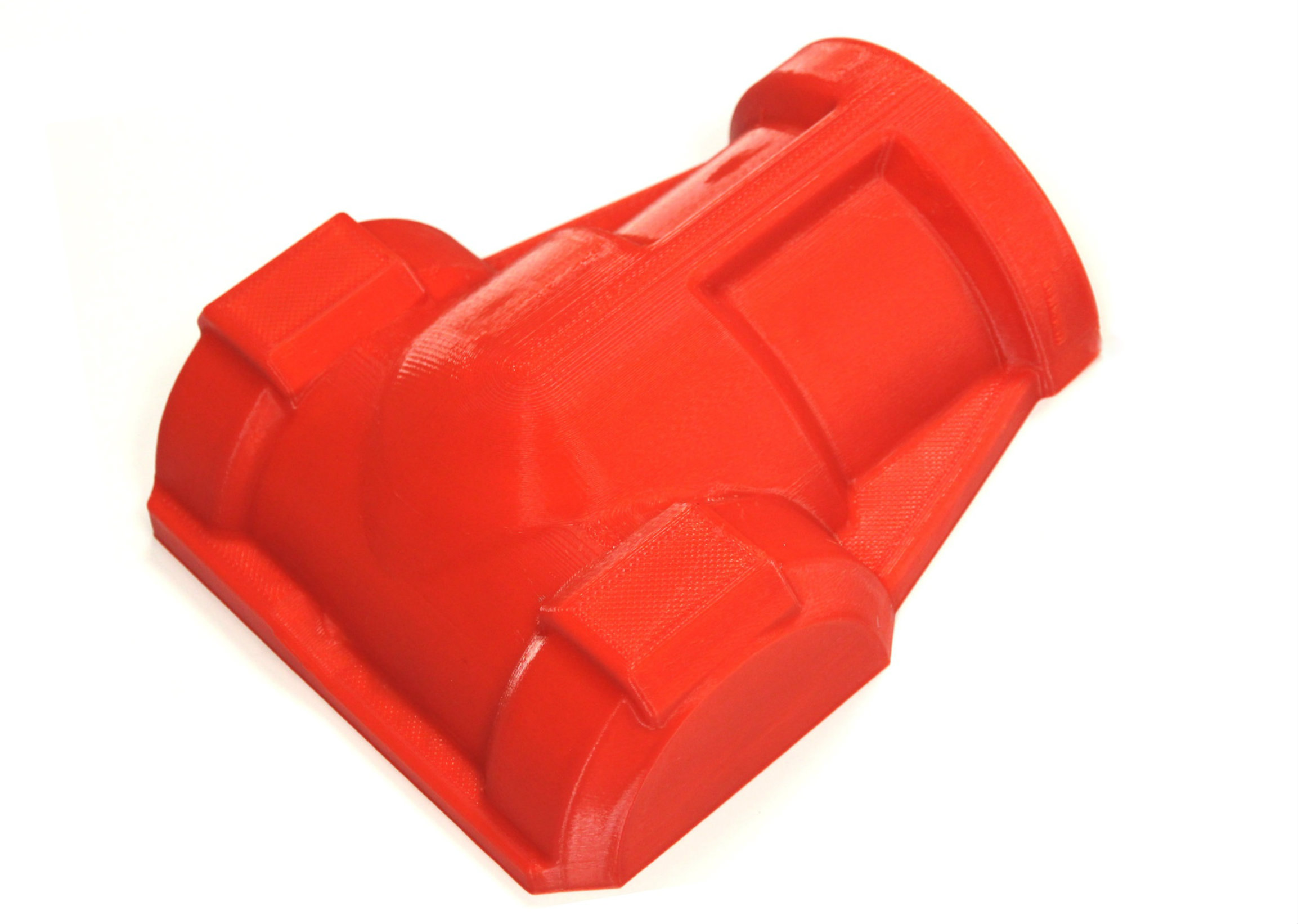

The AM1 allows for faster, cheaper, and more efficient pattern creation.

26 HRS

SHORT LEAD TIME

Two day turn around.

$52

LOW COST

Total cost to make a

pattern with the AM1.

MULTIPLE ITERATIONS

Making revisions is as simple as hitting print.

GENERAL LABOR

Anyone can manufacture with the AM1’s

intuitive quick-start process.

By working with Cosine, your company can provide a rapid turn around for your customers, and save money over traditional wooden pattern making techniques.

PATTERN CREATION TIMELINE

Traditional pattern mold making takes 4 weeks and costs an average of $5,000.

Working with Cosine allows you to streamline your process with the least amount of hassle.