Why are we still use the STL file format, I have no idea. My hope is that a true parasolid NURBS based slicing program is not far out. In the meantime, we are using a few tricks to show what is possible. Through custom hardware, firmware, and post processing, we finally implemented a workflow on top of the current STL slicers that shows what a vector based approach can do.

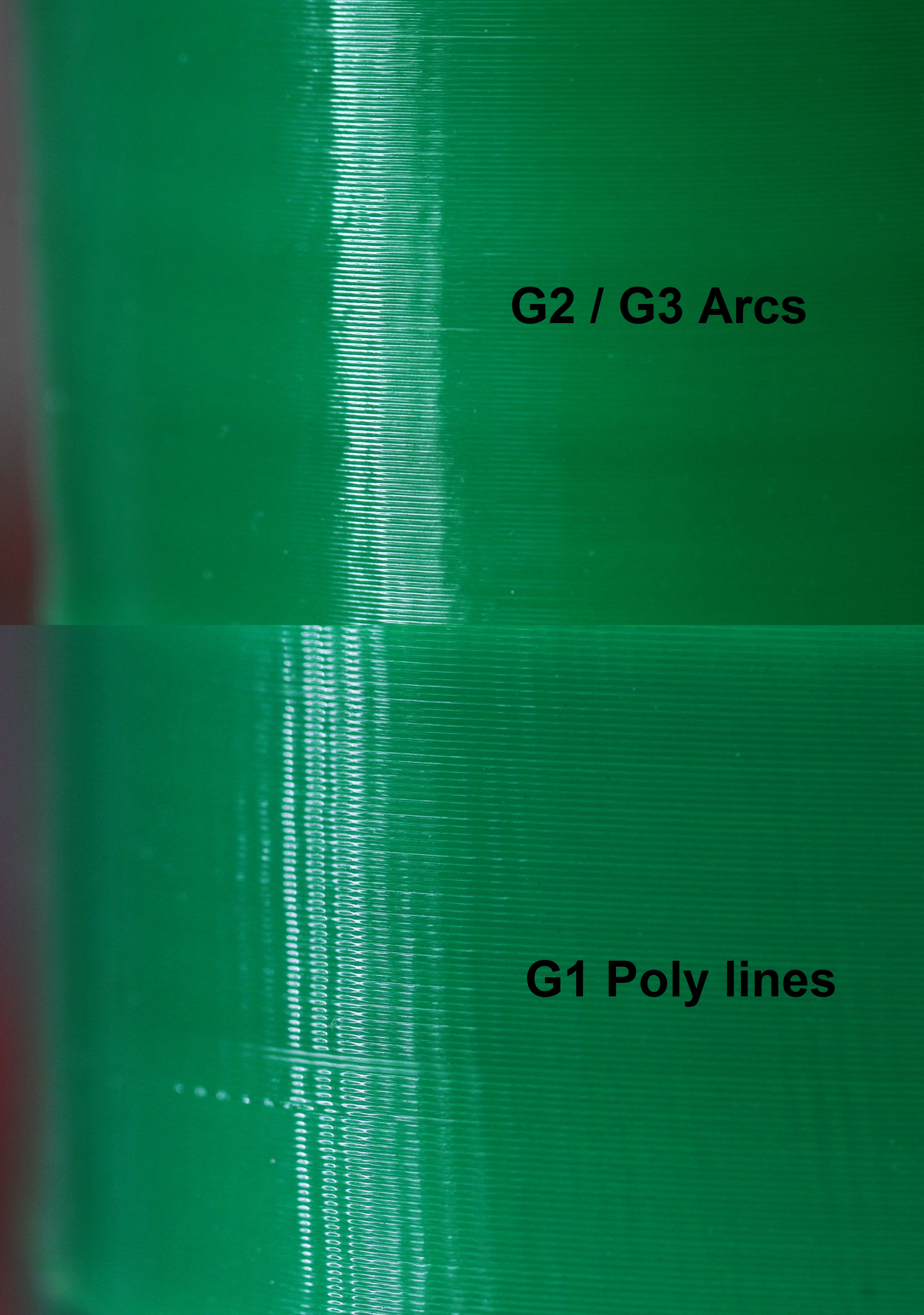

Here is a side by shot shot with the exact same geometry printed as an STL with G1 line-to-line type gcode vs. a G2/G3 arc based gcode. Note that servo tuning/jerk/accel settings all remained constant between the tests. The average STL facet size was 2mm. The approximate radius of this corner is 10 inches. Some of this is definitely a by-product of the larger mass of our system, but it goes to show how important a rigorous approach to smooth and continuous acceleration paths can be.

- Polycarbonate 3mm

- 70mm/sec

- .6mm Layer / 1.2mm road

- 3 contours