Loading Material has Never Been Easier!

The Cosine AM1 machines can be equipped with an automated pellet feed option, when installed the machine is equipped with material transfer tubes rated for vacuum pressure. The material is delivered via the rear-mounted material dryer tied into the hopper feed system using a closed loop vacuum system. A proximity sensor is installed to detect when the material in the hopper falls below a certain level which sends a signal that activates the automated pellet feed system.

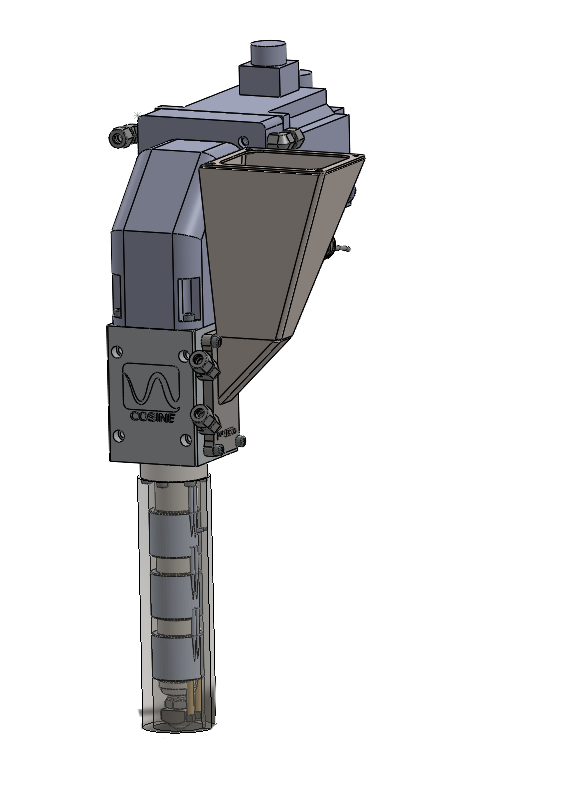

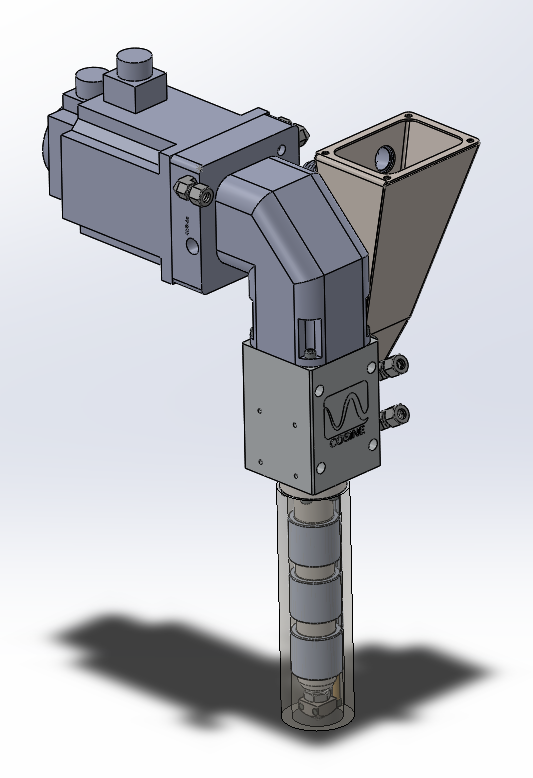

Cosine Gantry Sub Assembly

Since pellet based extrusion can achieve such high rates of extrusion when compared to traditional filament you need a system capable of delivering the material just as fast. Conventional forms of feeding in material can be limited to just a large hopper assembly that needs to be filled manually with material , but when you have prints that can be days long and need to run overnight you can easily run through pounds of materials in just a few hours. This automated feed option allows for peace of mind for continuous printing.

Some of the other pellet feed options you may see on the market can range from a melt pipe system to a simple compressed air method for delivering dried material. Some flaws of these compressed air systems is the air supply that drives the material can re-introduce moisture into the pellet material after its been dried, additionally it may also require extra support equipment or require access to a compressed air system. The Cosine closed-loop pellet feed system eliminates the opportunity for additional moisture to be re-introduced into already dried material nor does this system require additional support equipment outside of the AM1 machine assembly.

With a robust industrial FDM tool you need to have an equally reliable material delivery system. With Cosine pellet extruders rated for max extrusion at 20lbs/hour you need a nearly constant feed of material that the Cosine Pellet Feed system can deliver. Especially if you had a Cosine pellet extruder capable of max extrusion of 100kg/hour using 6 high-temp melt zones and a high-speed/high torque screw feed system….but that’s for another time!

Coming Soon

100kg/hour pellet extruder