Here, we list the different surface finishes that we offer at Cosine Additive. Our AM1 industrial 3D printer can offer various types of surfaces finishes. We also have in-house capabilities to give you the best product with the highest quality.

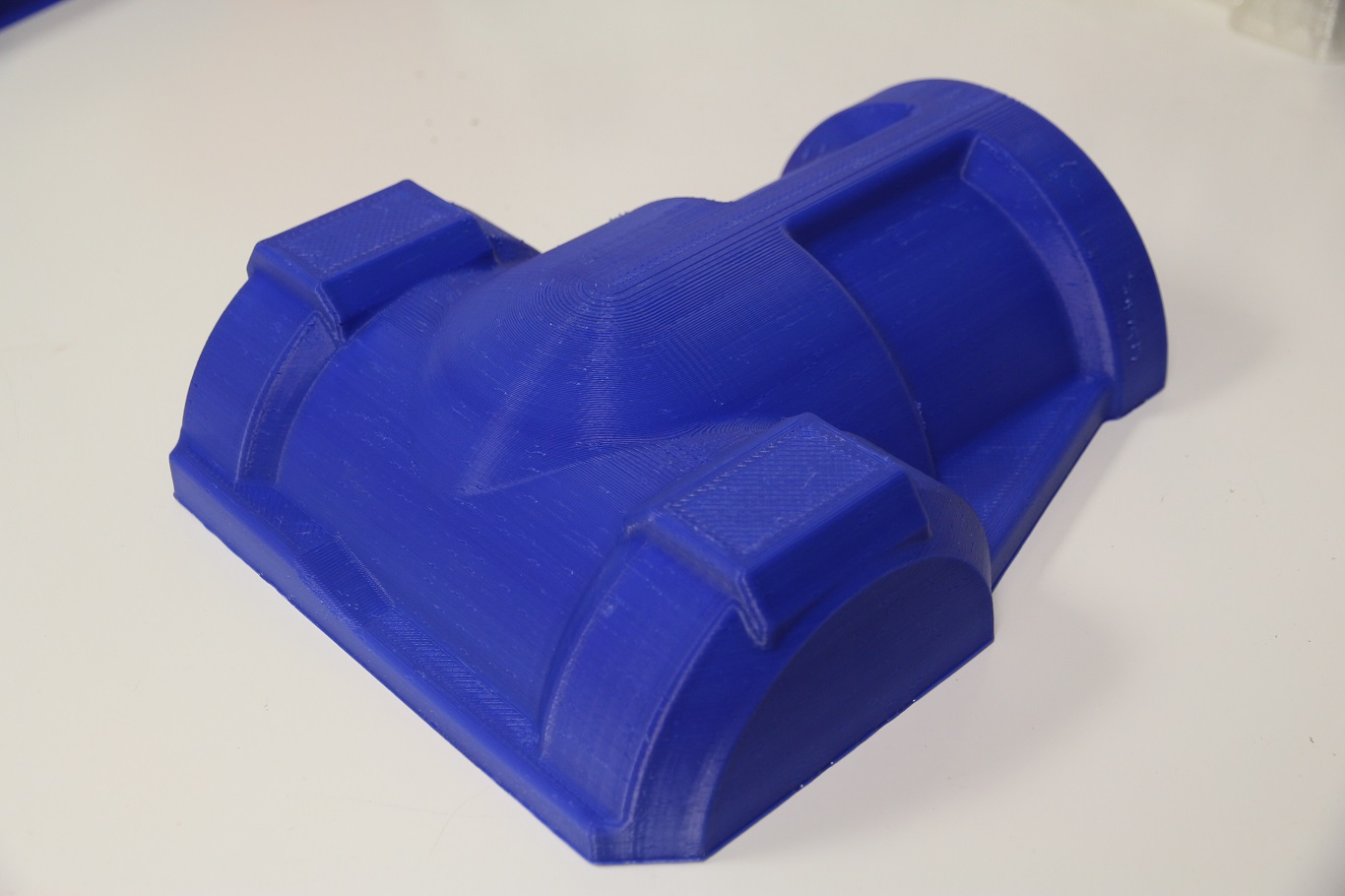

raw finish

The Raw finish is exactly how it comes out of the 3D printer. There are numerous settings on a large 3D printer that can determine the overall appearance of the part.

For precision and good looks, we suggest a smaller nozzle and a lower layer height.

For speed and strength, we suggest a big nozzle and thick layer height.

Thick Layer Height

If you don’t mind seeing the printing lines on the exterior layer, but you need the part ASAP, printing with a tall layer height is the answer for you. This setting will give you a fast printing time and will make any material stronger.

Thin layer height

If looks are important and you don’t mind the amount of printing time, a thin layer height will provide the best finishing looks.

Big Nozzle

A big nozzle will extrude more material, greatly reducing the time to print a part. Also, as the layer is thicker, it will provide the part with extra strength.

Small Nozzle

The small nozzles are all about precision. It will take a longer printing time, but the accuracy on laying the material will be second to none. Having a small nozzle size is the best way to guarantee the best finishing.

Materials

Different materials have different properties that will affect the print, and the overall end product.

Click HERE to see the different properties.

Machined

Besides 3D printing, we also provide CNC (computer numerical control). This means we can cut and carve different materials such as plastic, metal, and aluminum.

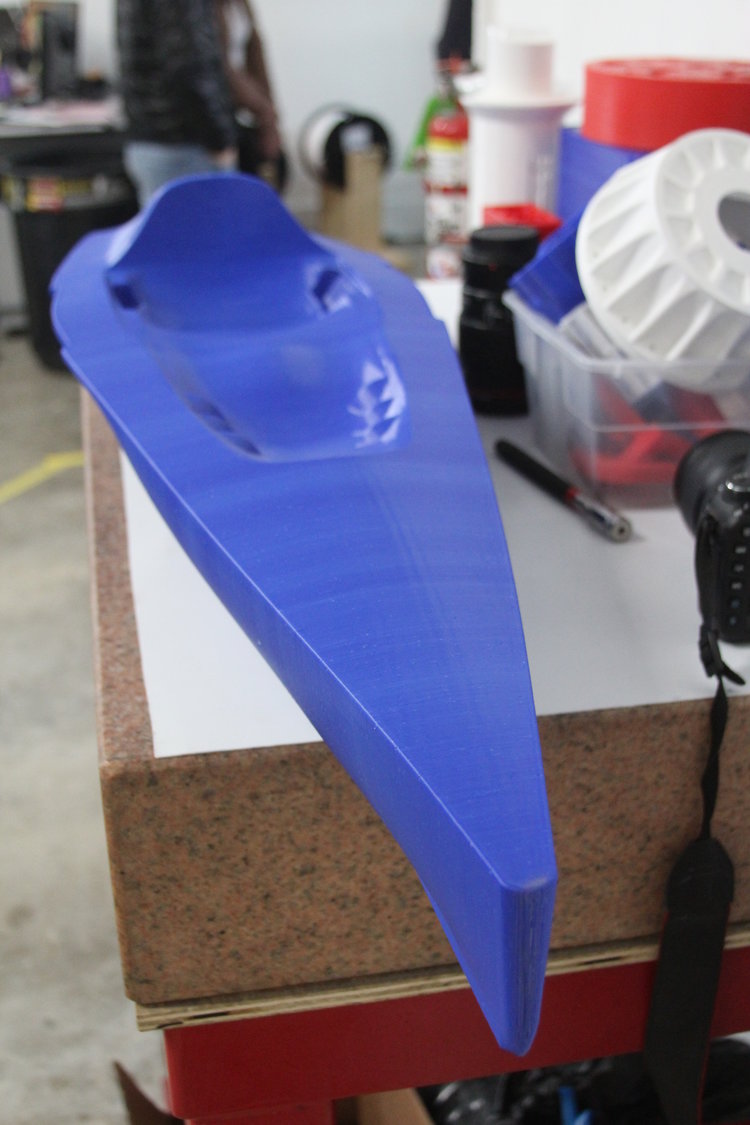

Acetone Bath / Vapor

Some plastics can be vaporized with Acetone to provide a super smooth finish.

If you are looking for a very aesthetically pleasing result, an acetone bath will provide you with a result you are looking for.

Sanding

A sanded finish gives the print a nice and smooth surface. By eliminating the imperfections on the layers, it allows us to prepare for painting, molding, or vacuum forming.

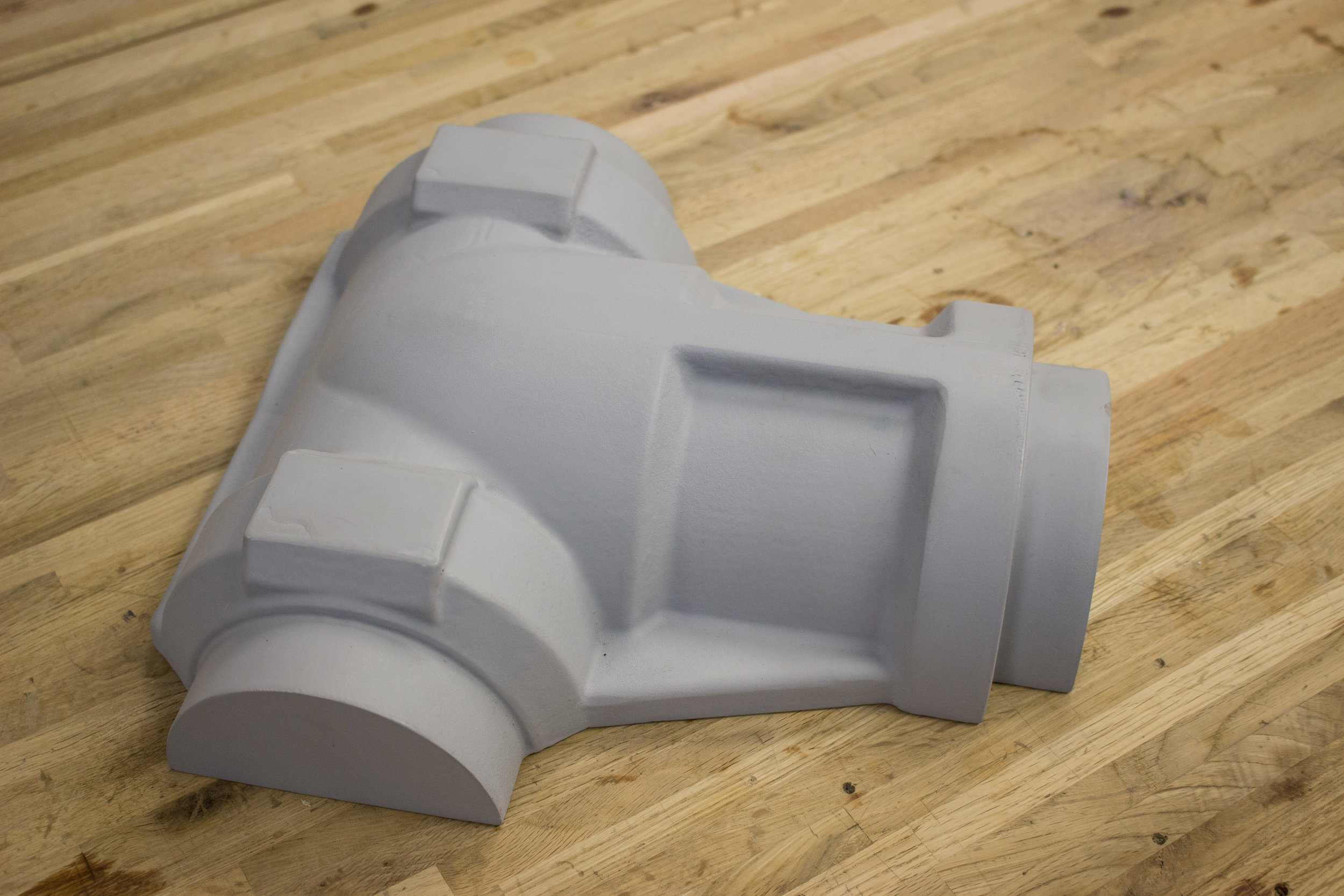

Priming

A primed part will have a preparatory coat on previously unpainted material, we use it to prevent the absorption of subsequent layers of paint, so the final coat of paint is perfect.

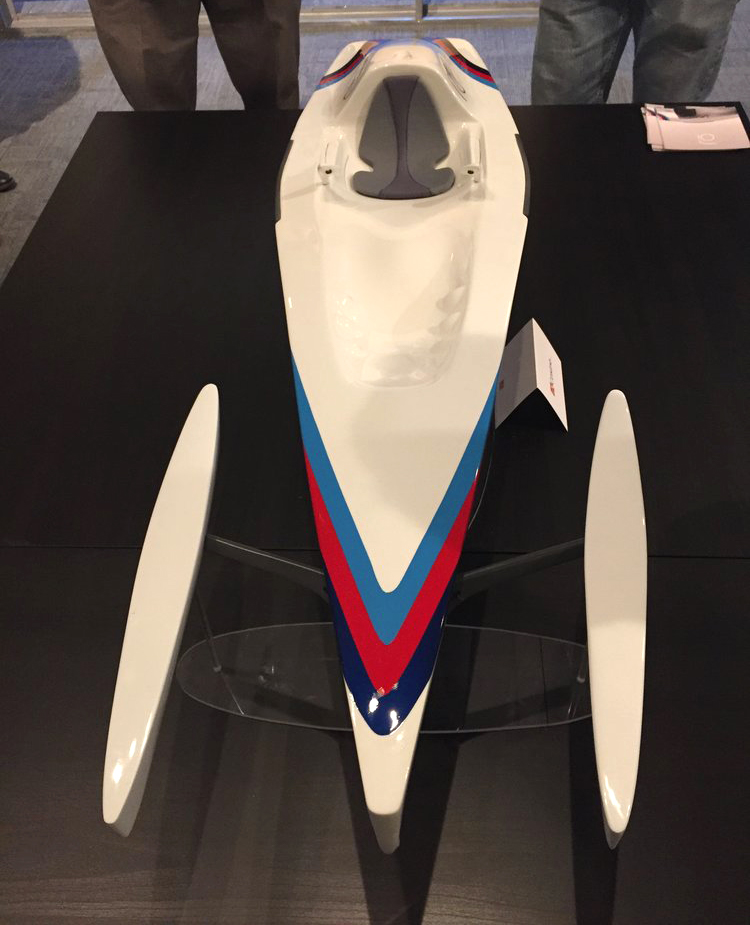

painting

This finish is ideal for giving your printed product a clean and professional look. We provide a variety of different colors to suit your needs and guarantee it will look exactly the way you envisioned.